Contents

Understanding 3D Printing Technology

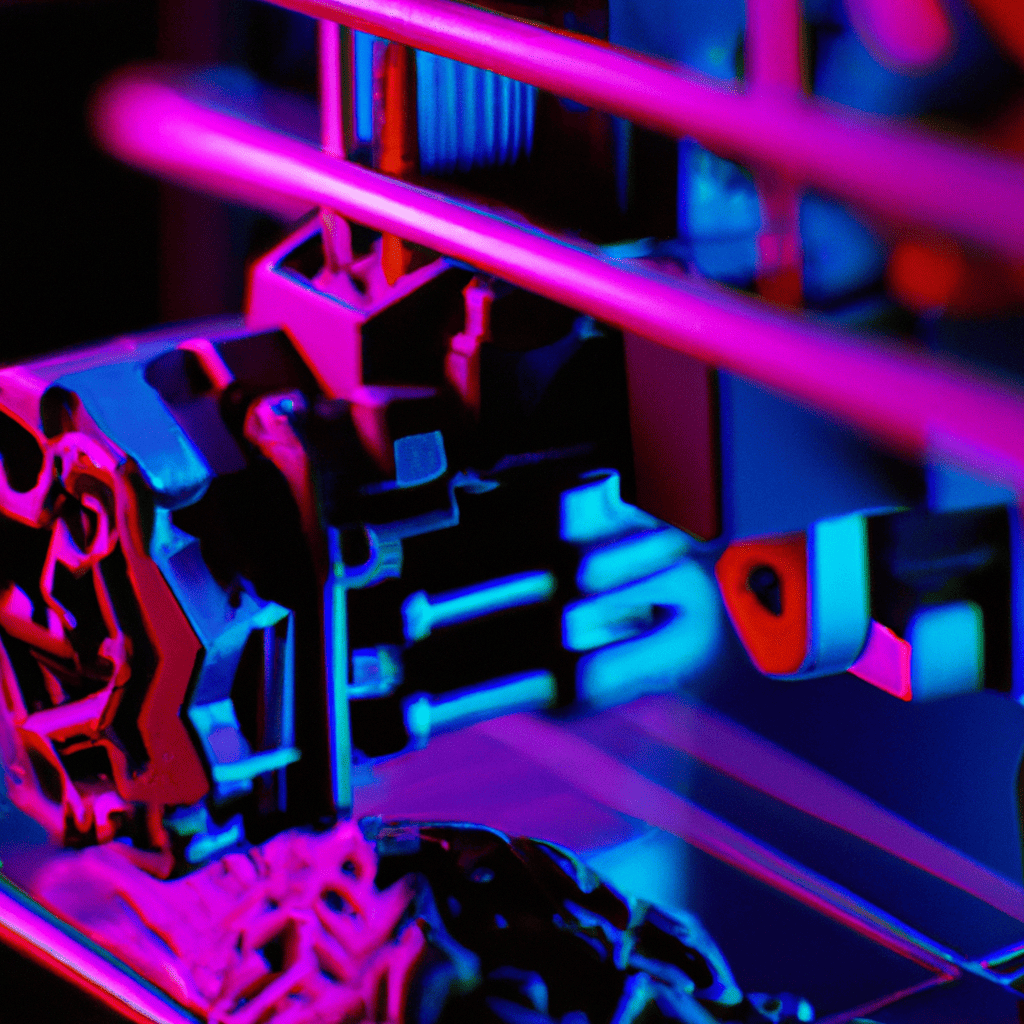

3D Printing technology is complex. To understand it better, let’s look closer at its print speed, quality, and printer performance. Print speed can range from 40-150mm/s depending on design and material. Print quality is determined by layer thickness and post-processing. Printer performance factors include build volume, extruder calibration, accuracy/precision, bed leveling and software compatibility.

3D printing can create complex shapes that are hard or even impossible with traditional methods. It can help you win contracts and get high customer satisfaction. Don’t miss out on the potential for growth it can bring. Speed is key when it comes to 3D printing – faster printing means faster progress.

Factors Affecting 3D Printer Speed

To learn how to increase the speed of your 3D printer, check out the Factors Affecting 3D Printer Speed section in What speed to expect from a 3D printer? This section will give you solutions to improve your 3D printing process with sub-sections like Print Quality vs. Print Speed and Printer Performance and Capacity.

Print Quality vs. Print Speed

When 3D printing, the quality versus speed of a print job is influenced by various factors. Printing temperature, nozzle size, layer height, infill density, and the printing material all have an impact.

Below is a table highlighting the key parameters affecting print quality versus speed:

| Parameters | Print Quality | Print Speed |

|---|---|---|

| Printing Temperature | Lower temp = better quality | Higher temp = faster printing |

| Layer Height | Thinner = higher resolution & slower | Thicker = lower resolution & faster |

| Nozzle Size | Smaller = better details & slower | Larger = compromised details & faster |

| Infill Density | High-density = sturdy parts & slower | Low-density = weaker parts & faster |

This interaction must be appreciated to make the right decisions that will have a positive effect on output quality. Balancing these factors is key to obtaining a mix of quality and speed for maximum efficiency. Missing out on this balance can mean your competitors will have an advantage regarding profitability and customer satisfaction. In 3D printing, performance is just as important as size – kind of like dating.

Printer Performance and Capacity

Here’s a table to show how various factors can affect printer performance:

| Factors | Effect on Printer Performance |

|---|---|

| Printing material | Speed and detail level of the print |

| Layer height | Thinner layers mean higher resolution but slower printing |

| Temperature control | Poor temperature settings lead to bad quality & longer printing time |

| Infill density | Higher infill density takes longer but makes stronger prints |

Speedier printers may be out there, but don’t let ‘fast’ be your only focus. Quality output is more important.

Calibrating your 3D printer can make a huge difference in print accuracy and smoothness. Plus, you’ll get better performance if you maintain it by cleaning & servicing regularly.

Average Print Speed of 3D Printers

To achieve the best results when using a 3D printer, you need to be aware of the full range of factors that can impact print speed and quality. In order to navigate this complex field, you can start by examining the different types of 3D printers and their respective speeds. Then, you can gain a more realistic understanding of what print speeds you can expect from your printer, based on a range of variables and performance metrics.

Types of 3D Printers and Their Speeds

Different kinds of 3D printers have varying printing speeds. Here is their average speed in mm/s:

| Type of 3D Printer | Average Print Speed (mm/s) |

| Fused Deposition Modeling (FDM) | 30-150 |

| Stereolithography (SLA) | 40-120 |

| Selective Laser Sintering (SLS) | 10-20 |

Each printer has distinct features that influence its speed. For instance, FDM printers use melted plastic for layers, which makes it speedy. On the other hand, SLA and SLS take more steps, resulting in slower speed. Other factors like size and complexity of the object also matter.

A research article in Materials & Design suggests that increasing extruder temperature can improve resolution but slow down FDM printers. So, if you’re looking for something fast, don’t get your hopes up too high.

Realistic Expectations for Print Speeds

Getting a quicker output from your 3D printer is essential. Print speeds depend on the type of printer and the temperature/layer settings. Here’s a table of popular 3D printer models and their average print speeds:

| Printer Model | Average Print Speed (mm/s) |

|---|---|

| Prusa i3 MK3S+ | 90-200 |

| Creality Ender 3 | 50-80 |

| Ultimaker S5 | 24-200 |

These numbers may change, but they give an idea of the speed to expect.

Not always is the speed the most important. Slower printing can result in better quality with intricate models or finer details.

To increase speed, optimize infill density, layer height, or use faster material. However, quality could suffer.

Trying to boost the speed of a 3D printer is like teaching a Sloth to dance – it takes lots of patience and effort.

Ways to Improve 3D Printer Speed

To improve the speed of your 3D printer, solutions lie in upgrading your printer and optimizing print settings. Printer upgrades and modifications can drastically improve print speed while maintaining high-quality prints. By making changes to print settings and optimizing them, you can shorten the time it takes to complete a print without sacrificing print quality.

Printer Upgrades and Modifications

Enhancing and modifying your 3D printer can help improve speed and efficiency, resulting in a boost in productivity. Here’s a table of the best upgrades and modifications:

| Upgrade/Modification | Description |

|---|---|

| Upgraded extruder | A high-performance variant can reduce filament jams and improve quality. |

| Upgraded hotend | A high-quality hotend allows for faster melting speeds and better flow control. |

| Dual-extruder setup | Using two extruders can decrease production time, as one nozzle prints support and the other prints the main object. |

| Heated bed | A heated bed ensures an even temp across printing surfaces and shorter cooling times between layers. |

| OctoPrint | OctoPrint enables WiFi connectivity for remote monitoring and management of prints. |

Be sure to research thoroughly before making any big changes – this will help increase speed, save time and resources, and improve production quality.

The 3D printing industry is always evolving, prompting more modifications to become available. If you want to print faster, make sure you use the right settings and optimize your printer – otherwise, you might get burned!

Print Settings and Optimization

To boost 3D printing pace, tweak and alter multiple elements of the printing process. These can be Print Settings and Optimization.

A table can help us understand how these settings influence print time and quality. Look at this schema:

| Type of Setting | Specific Setting | Impact |

|---|---|---|

| Temperature | Layer Height | Lower height increases print time but improves quality |

| Printing Speeds | Travel Speeds | Influence on time but no effect on output quality |

| Filament Type | Infill Density | Higher density leads to more material use and longer print times but improves strength |

Other aspects of printing optimization can cut down print time. Reducing the diameter or increasing the power available to the printer speeds up melt rate and quicker print times without affecting quality.

Adjusting Fan speeds also decreases time by cooling each layer faster.

Always keep in mind, faster 3D printing does not mean less quality!

Conclusion: Balancing Speed and Quality in 3D Printing

3D printing requires a perfect balance of speed and quality. To get the best print results, you have to slow down the speed of the printer.

Slowing down is not enough. You need to consider other factors like filament choice, temperature settings, and printer calibration too.

Low-end printers will affect both the speed and quality. Investing in high-performance ones like Ultimaker or Stratasys is ideal. Stratasys’ share price even surged by 36% after their Q2 2021 revenues of $147m.

So, pick a combination of printer performance and goals that will give you excellent 3D prints with great efficiency.

Frequently Asked Questions

Frequently Asked Questions:

Q: What speed can I expect from a 3D printer?

A: The speed of a 3D printer can vary depending on the model and settings, but on average, it can produce around 40 mm/s to 150 mm/s.

Q: Does the print speed affect the print quality?

A: Yes, the faster the printer works, the quality might be compromised. It’s essential to calibrate the settings to find the best balance between speed and print quality.

Q: How does the printer’s performance impact the print speed?

A: The printer’s performance can influence the print speed as it involves the accuracy of movement and the quality of printed parts.

Q: What factors affect the print speed?

A: The print speed depends on multiple factors, such as layer height, nozzle size, type of filament, and complexity of the design.

Q: Can I increase the print speed with a better printer?

A: Yes, you might be able to print faster with a better printer; however, it’s recommended to optimize the settings for the best balance between speed and quality.

Q: How can I improve the printing speed while maintaining good print quality?

A: You can improve printing speed while maintaining quality by adjusting the layer height, printing temperature, using a better nozzle, and choosing the correct filament type for the design.