Contents

Basics of 3D Printing

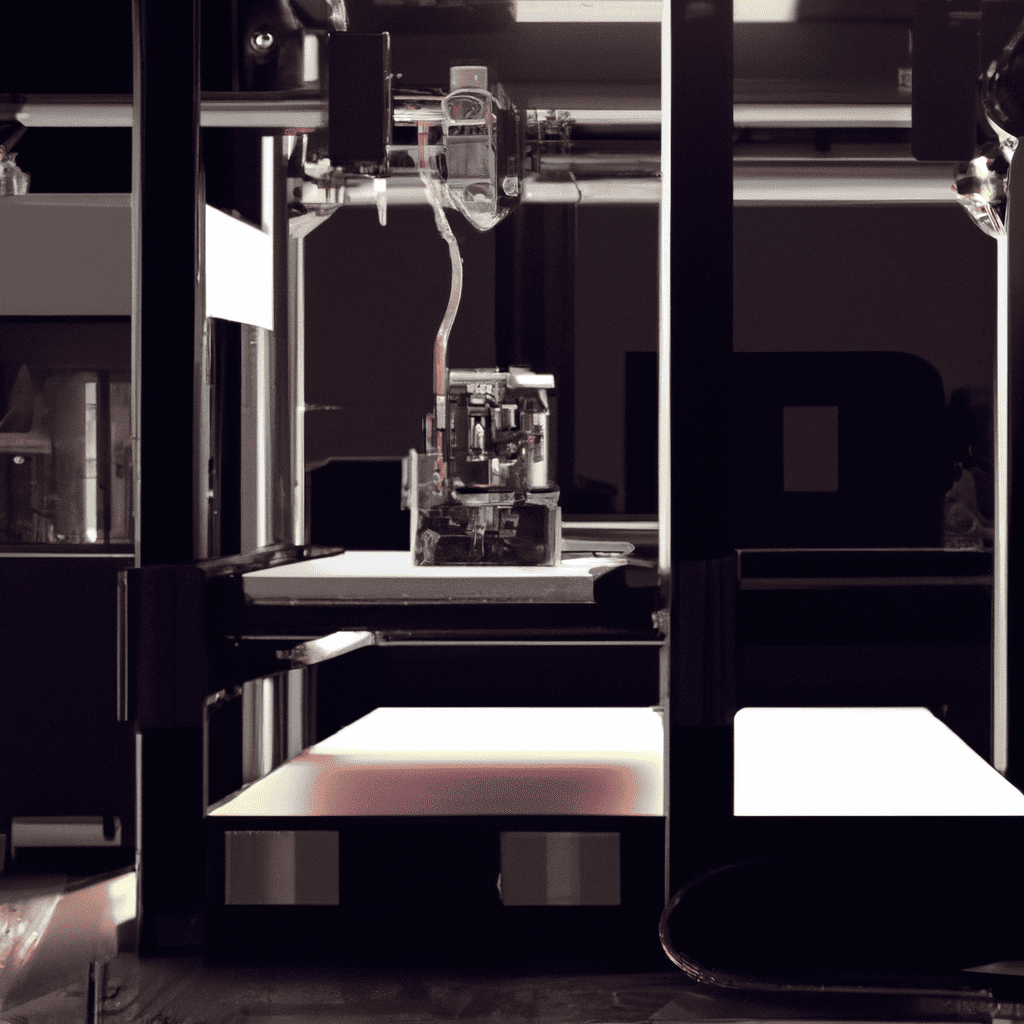

To understand the basics of 3D printing, with a focus on additive manufacturing and FDM technology, you can start by exploring the concept of what 3D printing is and its brief history. This will provide a foundation for understanding the different types of 3D printing technologies available. In this section, we will also explore the wide range of advantages that 3D printing offers.

What is 3D printing?

3D printing technology is a revolutionary process that allows you to create 3D objects layer by layer. You can use a digital representation and a wide range of materials, such as plastics, metals, and even food! With 3D printing, concepts can be brought to life without crossing geographical boundaries or incurring expensive costs.

The benefits are plentiful. You can create complex and unique designs with ease while reducing material waste. Plus, the process has a fast turnaround time and can make items that traditional manufacturing can’t. On top of that, it allows for customization according to individual preferences.

Software, like CAD, is important for designing models. You also need to select the right printing material for the object’s purpose and durability. To ensure quality, optimizing printer settings, like nozzle temperature and layer thickness, is necessary.

3D printing is used in a variety of fields, such as medicine, engineering, architecture, and art. Mass customization may become commonplace in the future with this technology’s advancements. As the industry continues to grow at a rapid rate, staying up-to-date with new technologies will be essential for success in the 3D printing arena. Yes, even pizza can be printed in three dimensions!

Brief history of 3D printing

3D printing technology has a lengthy history! It was first patented in the 1980s, but only gained traction in the early 2000s with more accessible and cheaper printers. Now, 3D printing is used in all sorts of applications, from manufacturing and healthcare to education and prototyping.

The process involves slicing a digital design into layers and building each layer sequentially. Materials like metals, plastics, or even living cells are used. This tech has come a long way and revolutionized many industries. It creates complex geometries, optimizes designs, and reduces time-to-market.

In fact, NASA even used this tech to produce tools on-demand in space missions, showing its versatility and quick adaptability. An amazing example of this tech is when researchers at Northwestern University in Illinois created an artificial ovary using 3D printing. It was still functional after transplantation into mice!

From Fused Deposition Modeling to Stereolithography and more, 3D printing can bring your ideas to life.

Types of 3D printing technologies

Different 3D Printing Techniques:

Various 3D printing techniques are used to transform digital designs into physical objects. Here are the types of 3D printing based on materials, printer type, and accuracy:

| Type | Printer Type | Material Used | Accuracy |

|---|---|---|---|

| Fused Deposition Modeling (FDM) | Extrusion-based | Thermoplastics, ABS, PLA, Nylon, Polycarbonate etc. | Low |

| Stereolithography (SLA) | Resin-based | Resin or photopolymer liquid cured by UV lasers. | High |

| Selective Laser Sintering (SLS) | Powder-based printers | Nylon, Polycarbonate or metals like titanium or steel powder. | High |

| Digital Light Processing (DLP) | Projector-based printers with resin material. | Photopolymer resin cured by light projection., for high-quality prints and prototypes. |

Plus, bioprinting is used in medicine to make living tissues and organs with biomaterials.

Pro Tip: Research before buying a 3D printer. It could have various features and technologies that may affect the print quality.

3D printing gives you the power to bring ideas to life – as long as it fits your printer’s size!

Advantages of 3D printing

3D printing offers many unique advantages. Cost savings in production and prototyping, design flexibility, complex geometries and faster delivery of products are just a few! Plus, it can use special materials, like metal powder or cells and tissue. It’s eco-friendly and perfect for creating intricate prototypes with extreme precision. Even NASA uses 3D printing on the International Space Station (ISS) to manufacture parts! It’s like building a sandwich – one layer at a time – except the bread is plastic and the filling is a complex design.

Additive Manufacturing Process

To understand the additive manufacturing process with a focus on basics of 3D printing, start with an introduction to additive manufacturing. Learn about the basic components of 3D printers and how they work. Discover the working principle of 3D printing as well as its main process, Fused Deposition Modeling (FDM). Lastly, we will briefly discuss other additive manufacturing processes.

Introduction to additive manufacturing

Additive manufacturing is a revolutionary process that builds complex 3D objects by layering material. It has changed many industries, including aerospace and healthcare. With this manufacturing process you can produce complex shapes without any restrictions from traditional methods.

Sub-methods of additive manufacturing include Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Stereolithography (SLA), and Digital Light Processing (DLP). All rely on computer-aided design data for creating objects layer by layer, but each has its own way of doing it.

Unlike subtractive manufacturing, where material is taken away to create a product, additive manufacturing makes less waste and can use recycled materials. This is an important factor in the current push for eco-friendly solutions.

Deloitte states that “the global market for 3D printing products and services reached $9.6 billion in 2019” and is continuing to grow. As technology develops and prices drop, additive manufacturing will become more common in many industries. So, get ready to become the Bob the Builder of the digital age as we explore the secrets of 3D printing!

Basic components of 3D printers

3D printing technology has many fundamental elements. These components make it possible to build 3D objects from a virtual blueprint. Here’s a list of the essential parts:

- Extruder: Pushes out molten material to create filament layers.

- Print bed: Where the object is made.

- Nozzle: Forms the first layer and guides the filament.

- Power source: Powers the print head and plate.

- Filament: Raw material for print layers.

You need special knowledge and skills to understand 3D printing. Different types of machines, like FDM printers and SLA printers, use different methods.

Robo 3D is a California-based company. They created 3D printers that could be used at home and cost just a few hundred dollars. They even have DIY kits so customers can build their own! Who knew you could use a printer to make amazing 3D objects with laser magic?!

Working principle of 3D printing

Additive Manufacturing is a modern process that uses 3D printing to make 3D objects from digital models. It works differently to traditional manufacturing techniques because it builds up an object layer by layer. The process involves slicing the model into thin layers and then depositing materials on top of each other until the final object is formed.

These objects are created using special machines called 3D printers. They can use plastic, metal and even living cells! This technology isn’t just for prototypes, it can also make complex shapes that other methods like injection molding cannot. Plus, modifications can be made during production with no extra tooling costs.

Additive Manufacturing has changed the game with its accuracy and capabilities. Now, prosthetics can be produced with precision details and better fitment for patients.

This all started with Chuck Hull who invented stereolithography in 1983. He opened the door for Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS). These cutting-edge techniques are now used in many industries, from aerospace to medical.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is an Additive Manufacturing Process. It involves melting and extruding thermoplastic filaments layer by layer to create 3D objects.

The Table below shows the features of FDM Technology.

| Fused Deposition Modeling | |

|---|---|

| Technology type | Extrusion |

| Materials used | Thermoplastics |

| Print speed | Slow to Medium |

| Surface finish | Rough |

FDM technology stands out due to its ability to make parts with different densities. This can be achieved by adjusting the infill settings, resulting in lighter, stronger, and more efficient end products.

Pro Tip: To get high quality prints, the FDM printer must be well maintained and calibrated.

Ready to explore more? Additive manufacturing is much more than 3D printing!

Other additive manufacturing processes

Expanding the scope of 3D printing, there are other methods used in the current era. These ‘additive manufacturing processes’ are used for prototyping since the 1980s, and are now gaining traction in specialized areas like medical implants and aerospace components.

A table of different additive techniques is listed below:

| Additive Process | Materials Used | Key Features |

|---|---|---|

| Binder Jetting | Ceramic, Metal, Sandstone, Plastic | High-res prints at low cost |

| Directed Energy Deposition (DED) | Metals & Alloys, Niobium Alloy C103 (Superalloy) | Customizable prints with high density/structural integrity |

| Material Jetting or Drop On Demand (DOD) Inkjet Printer Method | Photopolymer, Wax, Ceramics | Faster print speed than conventional technologies |

| Sheet Lamination or Ultrasonic Additive Manufacturing (UAM) | Aluminum Alloys & Copper Powder composite materials | Creates smooth surfaces with intricate designs |

| Vat Photopolymerization – DLP/SLS/LCD Printers etc. | Photopolymer Resin, Wax, Plastics | Superior print res with less labor-intensive |

A new category of additive manufacturing is being explored – Hybrid Additive Manufacturing (HAM). This process combines additive techniques with traditional CNC practices. HAM helps fabricate parts by merging the unique advantages of both types of manufacturing.

Businesses know the value of innovation. It’s important to be aware of the range of additive manufacturing processes and their strengths. Implementing these technologies can bring economic results and productivity across industries.

Don’t miss out! Explore how these technologies can supercharge production today! 3D printing is like baking a cake, but with materials like plastic, metal, and even chocolate!

Materials Used in 3D Printing

To understand the materials used in 3D printing and make informed decisions, equip yourself with knowledge on the types and characteristics of 3D printing materials. In this section of “What is a simple explanation for understanding 3D Printing?”, we explore the sub-sections on the different types of materials used in 3D printing, the characteristics that make them unique, and how they compare to each other.

Types of materials used in 3D printing

3D printing has revolutionized the way materials can be used to create three-dimensional objects. Here are some of the materials that can be employed in this process:

- PLA (Polylactic Acid), a biodegradable material made from renewable resources;

- ABS (Acrylonitrile-butadiene-styrene) – a thermoplastic polymer;

- PETG (Polyethylene Terephthalate Glycol) – strong and flexible;

- Nylon – high strength and flexibility; and

- Metal – such as titanium, aluminum, steel or copper.

Exotic materials are also available for specialized uses. For example, conductive filaments enable printing of designs with integrated electronics, while carbon fiber reinforced resins can create sturdy yet lightweight parts.

Sculpteo’s study shows that PLA and ABS are the most popular 3D printing materials, with over 80% usage. So, make your wildest creations come to life with these amazing materials!

Characteristics of 3D printing materials

3D printing materials possess special traits that determine their aptness for various applications. We’ve put together a table to make it easier for you to comprehend these traits. It displays material type, melting point, strength, and flexibility.

| Material Type | Melting Point (°C) | Strength (MPa) | Flexibility (Shore A) |

|---|---|---|---|

| PLA | 170-190 | 30-60 | 65-95 |

| ABS | 210-250 | 20-40 | 75-100 |

| PETG | 230-260 | >50-70 | >90-</diamete5 |

From this table, you can see that different materials have distinct strengths and flexibilities. And some require higher temperatures for melting and printing. Also, certain materials are more suitable for certain applications. Thus, it’s essential to know the one-of-a-kind characteristics of each material to pick the right one for your task.

Pro Tip: Always go for superior quality filaments when carrying out 3D printing projects – this will determine the result’s quality. If you believe all 3D printing materials are similar, you must be PLA-ying a joke on me.

Comparison of different 3D printing materials

3D printing has revolutionized many industries by allowing for the creation of complex and customizable objects. Materials used in 3D printing are crucial–it’s important to understand their properties and how they differ. Reference the table for the most commonly used materials, their strengths and weaknesses, and compatible printers.

| Material | Strengths | Weaknesses | Compatible Printers |

|---|---|---|---|

| ABS | Durable and impact-resistant | Emits toxic fumes when printing | Fused Deposition Modeling (FDM) |

| PLA | Biodegradable | Brittle and has low heat-resistance | FDM |

| PETG | Flexible and has a strong bond | Can be difficult to print quickly | FDM |

| Nylon | High strength-to-weight ratio | Absorbs moisture easily and can be tricky to post-process | FDM, Selective Laser Sintering (SLS) |

| Metallic Filaments | Gives a realistic metal finish | Expensive and requires specialized equipment | FDM |

| Resin-based materials | Great for high-detail and glossy prints | Comes with expensive and toxic chemicals during printing | Stereolithography (SLA) |

These materials aren’t the only ones out there. For example, woodfill filament gives prints a wooden texture while rubber-like filaments like TPU offer flexibility. Some materials may need specific nozzle diameters and heated build plates.

Keep up with the latest materials and techniques for 3D printing. Stay curious, explore, and never stop innovating! Who needs a genie when you have a 3D printer? The possibilities are endless!

Applications of 3D Printing

To understand the range of applications of 3D printing, dive into this section with its sub-sections – Overview of 3D printing applications, Industrial applications of 3D printing, Medical applications of 3D printing, and Consumer applications of 3D printing. These sub-sections discuss the diverse fields where 3D printing has transformed the production process and impacted society, ranging from mass production to innovative medical procedures.

Overview of 3D printing applications

3D Printing: A World of Possibilities!

It’s no surprise 3D printing is getting popular. It’s transforming how products are designed, produced, and manufactured. Check out the range of applications it covers in different industries:

- Healthcare: prosthetic limbs, dental models, implants, and surgical instruments.

- Aviation: aircraft and engine parts.

- Fashion: wearable fashion and jewelry.

- Architecture: scale models of buildings.

- Education: educational models.

Plus, 3D printing can make replacement parts for machines, quick prototypes for R&D teams, and personalized products for customers.

Did you know NASA uses this tech to create rocket parts? 3D printing: cars, prosthetics, and even houses – it’s like real-life Minecraft!

Industrial applications of 3D printing

3D printing has become common in lots of industries. It’s a creative and economical way to make unique designs and parts that are hard to create using classic methods.

The table below shows how 3D printing is used in different businesses:

| Industry | Applications |

|---|---|

| Aerospace | Prototyping, component production |

| Automotive | Prototyping, tooling, molds |

| Healthcare | Prosthetics, implants, surgical guides |

| Construction | Building components, rapid prototyping |

| Fashion | Customized clothing and accessories |

3D printing is special. It helps make shapes that classic manufacturing can’t. This has changed design ideas.

Chuck Hull invented 3D printing in the mid-1980s. It was made for quick prototyping in automotive manufacturing. But since then, it has been used in many other areas like aerospace and healthcare. Why bother going to medical school when you can just 3D print a new organ?

Medical applications of 3D printing

The union of 3D printing and medical treatment has completely changed the medical field! Prosthetics can make difficult operations more straightforward and provide tailor-made prosthetics. Bio-printing enables the production of precise copies of human organs for research, testing, and transplants. Surgical planning can give precise and precise analysis for surgery planning, lessening complications during the process. Moreover, 3D printed models are used in medical learning. They allow pupils and surgeons to rehearse surgical strategies on life-like models before operating on living people.

Pro Tip: With the increasing necessity for trained personnel able to operate and create software for 3D printing in medical facilities, grasping this technology can expand your job chances in the healthcare industry. Printing your own iPhone case with a 3D printer is like doing your own plastic surgery for your phone!

Consumer applications of 3D printing

Text: 3D Printing in Consumer Industry

A game-changing advancement in modern technology, 3D printing has changed the way products are made. It’s becoming more and more popular across different industries, particularly in the consumer industry.

Various Applications of 3D Printing in Consumer Industry

| Category | Description |

|---|---|

| Fashion | 3D printing tech can be used to create customized shoes, accessories and clothing to suit individual preferences. |

| Healthcare | Doctors can make personal tools and prosthetics that fit perfectly to a patient’s body measurements. |

| Food Industry | With 3D printers, intricate food designs and shapes can be created easily, enhancing the food experience. |

| Home Decor | Consumers can design unique home decor items with their personal style, such as lampshades and vases. |

Revolutionizing the Way Consumers Create Products

The flexibility provided by 3D printing for creating special designs matches consumer needs for a wider choice than mass-produced products. So, there’s a big move towards personal product design in the consumer industry.

Join the Wave of Innovation

As technology advances quickly, it’s important for consumers to stay up-to-date. Don’t miss out on this new manufacturing era! Explore the revolutionary world of 3D printing technology before the others overtake you.

Why buy it when you can print it? 3D printing enthusiasts and hoarders will shape the future.

Future of 3D Printing

To understand the future of 3D printing with its technological advancements, potential impact on various industries, and challenges for wider adoption, keep reading. In this section, you’ll gain insights into how this additive manufacturing technology is evolving and how it could revolutionize numerous fields in the coming years.

Technological advancements in 3D printing

Revolutionary 3D printing has totally changed the manufacturing industry. Utilizing additive manufacturing techniques, complex designs can now be created with ease.

A glimpse of the ‘Technological Advancements in 3D Printing’ table shows the effect of new materials, speed, and accuracy on the industry. Metal powder and ceramics have made way for higher quality production, perfect for medical, aerospace, and automotive sectors. Complex software has boosted print speeds, not compromising output quality, and improved layer thickness precisely.

For sure, Improved Environmental Sustainability is a special result of 3D printing. There is less waste material used for production, transforming procurement processes and still keeping up high-grade products.

Based on ResearchAndMarkets.com report, “Global 3D Printing Market Outlook 2030”, a CAGR of almost 20% is predicted from 2021 till 2030.

3D printing is making the phrase ‘out of thin air’ real for architects, engineers, and designers.

Potential impact on various industries

3D Printing is revolutionary technology with the potential to transform various industries including Manufacturing, Healthcare, Construction, Automotive, and Aerospace. These industries will all be impacted by 3D printing, in ways such as cost-effective prototyping, customized prosthetics, intricate structures with less waste, lightweight car parts, and accelerated development processes.

The tech is also emerging in other innovative areas such as food safety, dietary requirements, food waste, and supply chain management. Testing is even underway to print human organs, which would drastically reduce organ transplant waiting lists.

Don’t be left behind in this revolutionary era – companies who adopt 3D printing will enjoy competitive advantages that those who don’t will miss out on. But we must address the challenges of cost, scalability, and reliability before this groundbreaking tech can truly reach its potential. Don’t wait until it’s too late – start exploring 3D printing today!

Challenges to be addressed for wider adoption of 3D printing.

The adoption of 3D printing has many barriers to overcome. Key among them is the cost of materials and specialized equipment, as well as quality control issues. Also, post-processing and finishing slow down production and increase costs.

To make 3D printing more accessible, materials and tools need to be made more affordable. Governments and organizations could partner to fund research into alternative materials that are cost-effective and maintain quality. There also needs to be more standardization of software development to achieve uniform outcomes.

A revolution in 3D printing is the size of the printers. They are becoming increasingly small, portable, and popular.

3D printing technology first emerged almost four decades ago in Japan as Rapid Prototyping (RP) or Additive Manufacturing (AM). Chuck Hull invented Stereolithography Apparatus (SLA). This led to companies like Formlabs, which started with a Hornbeam tree as a material for SLA. Selective Laser Sintering (SLS) and Fused Deposition Modelling (FDM) were developed from this era. Nowadays, printers are capable of making intricate products within hours.

Frequently Asked Questions

1. What is 3D printing?

3D printing is a form of additive manufacturing that involves layering materials to create a three-dimensional object.

2. How does 3D printing work?

3D printing works by digitizing an object and then slicing the digital file into layers, which are then printed layer-by-layer using a 3D printer until the object is complete.

3. What materials can be used for 3D printing?

A variety of materials can be used for 3D printing, including plastics, metals, ceramics, and even food and human tissue.

4. What is FDM?

FDM stands for Fused Deposition Modeling, which is a common type of 3D printing technology that uses melted plastic or other materials to create 3D objects layer-by-layer.

5. What are some common applications of 3D printing?

3D printing is used in a variety of industries, including healthcare, aerospace, automotive, and product design to create prototypes, parts, and even finished products.

6. What are the benefits of 3D printing?

3D printing can save time and money by reducing the need for traditional manufacturing methods, allowing for customized designs, and enabling rapid prototyping and iteration.