Contents

- Factors that affect 3D printing time

- Print speed and its impact on 3D printing time

- Layer height and its impact on 3D printing time

- Print volume and its impact on 3D printing time

- Material type and its impact on 3D printing time

- Design complexity and its impact on 3D printing time

- Frequently Asked Questions

Factors that affect 3D printing time

Factors That Influence the Time Taken for 3D Printing

Print speed, layer height and print volume all affect 3D printing time. The table below shows how these factors influence printing duration.

| Factor | Description |

|---|---|

| Print Speed | The rate material is deposited for each layer |

| Layer Height | The thickness between layers |

| Print Volume | The size of the model being printed |

Infill density and thread width configuration can also shorten the print time. Earlier printers used to reduce electronic components to increase torque and motor speed, which quickened printing times. But now, software modifications are used instead of hardware upgrades.

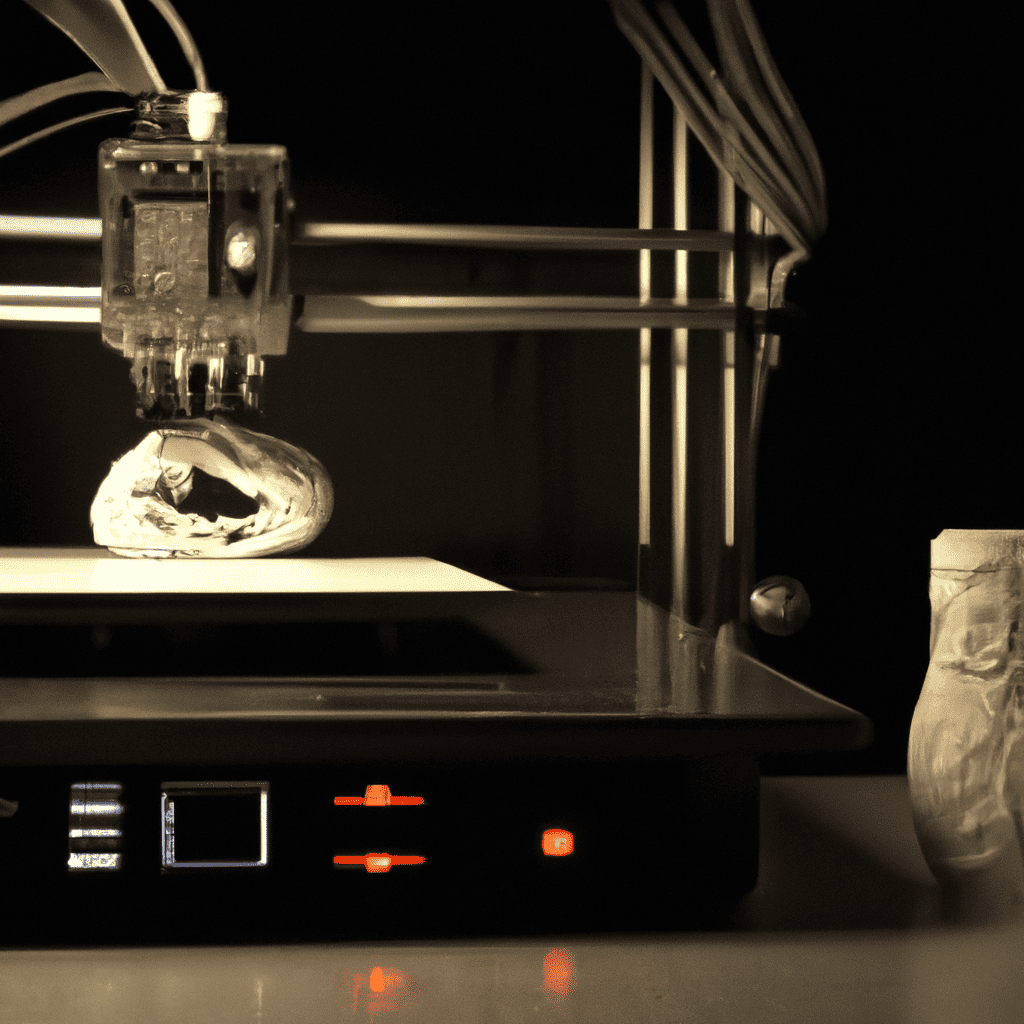

Quick print speeds can save time when 3D printing.

Print speed and its impact on 3D printing time

To optimize your 3D printing time, it’s important to understand how print speed impacts your final print. In order to dive deeper into this topic, the following sub-sections will provide an overview of the two important factors to consider. First, we will examine the relationship between print speed and layer height, and secondly, we will explore the effect of print speed on the quality of the print.

The relationship between print speed and layer height

When it comes to 3D printing, speed impacts the time it takes to print a model. Higher speed = faster printing. But, this can affect layer height & surface quality.

We showcase layer heights & print speeds, and their printing times for a standard object. As the layer height decreases, printing time & quality increase. High speed with low layer height can cause under-extrusion, which affects surface finish.

Find a balance between speed & quality. Setting higher speed doesn’t necessarily mean faster printing time. It depends on the filament properties of each printer.

Pro Tip: Experiment with different settings & material properties. Incremental changes can result in optimal 3D prints within reasonable timescales. Slow & steady may be the norm, but speedy & steady wins the 3D printing quality race.

The effect of print speed on the quality of the print

Print Speed’s Impact on the Quality of 3D Prints.

Faster print speed means worse quality. Finding the right balance is key. Check out the table below to see how speed affects PLA filament prints with a 0.4mm nozzle.

| Print Speed (mm/s) | Quality | Time (hh:mm) |

|---|---|---|

| 30 | Good | 07:35 |

| 40 | Decent | 06:12 |

| 50 | Poor | 05:14 |

High speeds can cause under-extrusion and loss of detail. Different materials and printers will give different results.

The takeaway: Printing slower than the max speed can give you better quality prints – but it’ll take longer.

Why settle for superb when you can have twice as tall super-duper?

Layer height and its impact on 3D printing time

To optimize your 3D printing time for better output quality and efficiency, you need to master the concept of layer height and its influence on your print speed. With this [section] on “Layer height and its impact on 3D printing time” with [sub-sections], you get to learn how layer height is related to print time, and how it affects the quality of your print.

The relationship between layer height and print time

Layer thickness has real influence on 3D printing time. When you put thinner layers on the print bed, more of them are needed to finish the object, leading to extended hours of printing. Also, the size and complexity of the model can affect the time taken.

For example, a small bowl that is 5cm x 5cm-sized requires different printing hours for various layer heights. See the table below:

| Diameter (5cm) | Height (5cm) | Layer Thickness (mm) | Print Time |

|---|---|---|---|

| 0.1mm | 9hrs | ||

| 0.2mm | 4hrs | ||

| 0.3mm | 3hrs |

Using thinner layers for 3D printing results in more accurate prints, however, it also means more time to finish the job. It’s like selecting between an HD TV and an old tube one – the decision affects both quality and time you’ll have to watch it. ‘Materials Today’ survey confirmed that.

The effect of layer height on the quality of the print

Layer height is a major factor in 3D printing. It affects both the time it takes to print and the product’s quality. A small layer height means smoother details, but can take longer. A higher layer height saves time, but the end result is less detailed.

To show the effects of layer height on time and quality, we created a table. We kept all settings the same, except layer height.

| Layer Height | Time Taken | Quality |

|---|---|---|

| 0.1mm | 5 hours | Smooth finish with intricate details |

| 0.3mm | 1 hour | Coarser with visible lines |

Changing the layer height can also affect adhesion and support structures. Before you begin your project, consider every aspect and weigh up the pros and cons of print quality vs. print time. Don’t miss out on optimal results due to the wrong layer height!

Print volume and its impact on 3D printing time

To optimize your 3D printing time, you need to consider the print volume. With larger print volumes, the print time is significantly increased, impacting the overall efficiency of the process. In this section, “Print volume and its impact on 3D printing time,” we will discuss how print volume affects print time, and how it can impact the quality of your print.

How print volume impacts 3D printing time

Print Volume and its Impact on 3D Printing Time.

The size of a 3D print affects the time it takes to complete it. A small print has a short printing time, medium size prints take moderate time, and large prints take a long time. This is because bigger prints need more material and more layers, which increases the printing time.

Other factors like printer resolution and design complexity also have an effect on the printing time. Knowing how the print volume affects printing time can help to optimize production and reduce costs.

It’s amazing that 3D printing has come so far since it was first used in the 1980s for rapid prototyping in manufacturing. Now, it is used for many things, like healthcare prosthetics and aerospace engineering. I may not have the biggest print volume, but I make up for it with quality and speed!

The impact of print volume on the quality of the print

Print volume has a great influence on the quality of 3D prints. A bigger print volume often needs more time to finish printing. This can cause problems like underextrusion, layer shifting and warping, which all affect the quality of the 3D print. Check the table below:

| Print Volume (in cubic cm) | Time Taken for Printing (in hours) | Quality |

|---|---|---|

| 100 | 2 | High |

| 250 | 4.5 | Medium |

| 500 | 9.5 | Low |

As the print volume rises, the printing time increases and the quality goes down. Also, printer settings and material type have an effect on the quality of the 3D print.

Nowadays, people prefer larger scale prints because of advanced technology. But it is essential to balance size and efficiency while maintaining high-quality prints. Using the wrong material is like fighting with a spoon instead of a sword.

Material type and its impact on 3D printing time

To understand how material type affects 3D printing time in a professional setting, let’s discuss the solution that the section on ‘Material type and its impact on 3D printing time’ with the sub-sections – ‘The effect of material type on print time’ and ‘The impact of material type on the quality of the print’ can provide. These sub-sections will explore how different material properties such as viscosity, strength, and durability can impact both the time it takes to print a model and the final quality of the print.

The effect of material type on print time

Material choice makes a big difference when it comes to 3D printing time. There are different materials used for 3D printing, and each one affects print time differently. Here’s a look at how different materials affect print time:

| Material Type | Print Time (in hours) |

|---|---|

| PLA | 4 |

| ABS | 7 |

| Nylon | 10 |

| Polycarbonate | 12 |

Note that material is not the only thing that influences print time. Other factors like model complexity and printer settings can also play a role. Knowing the differences in printing time between material types helps to boost productivity.

Innovative materials such as wood pulp, metal powders, and recycled beer bottles are becoming more popular due to their unique properties. These materials may bring benefits, but they may also take longer to print because of their complexity.

Ambient temperature, humidity, room ventilation, and other variables can also affect printing speed. Power cuts during long printing hours can lead to wasted time and resources, so it’s important to choose sturdy hardware. The wrong material could make your 3D print look like a Pinterest fail.

The impact of material type on the quality of the print

Different materials have distinct effects on the quality of 3D prints. They can determine texture, strength, and finish. So, selecting the right material is critical for a desirable outcome. Here’s a breakdown of how materials impact 3D printing:

| Material type | Impact on quality |

|---|---|

| ABS plastic | Durable and heat-resistant. But, it can warp and must be printed in a ventilated area. |

| PLA plastic | Eco-friendly, easy to print, and smooth. But, it is less durable than ABS. |

| Nylon Plastic | Flexible, strong, and resistant to wear. But, it requires high printing temperatures. |

Different materials could produce varied results based on their bonding ability with other layers during printing. So, choosing the appropriate material is essential for producing useful end products.

It is worth noting that 3D printing dates back to the early ’80s when Chuck Hull invented Stereolithography (SLA). It uses UV-sensitive liquid resins hardened by laser light. Nowadays, 3D printing technology has improved to support various materials such as plastics, metals, ceramics, and even biological tissues.

Warning: The more intricate your design, the longer you’ll wait for your 3D printer. Cue Jeopardy theme music.

Design complexity and its impact on 3D printing time

To optimize 3D printing time with high-quality output, explore design complexity and its impact on the process. Discover how design complexity impacts 3D printing time and learn about the effect of design complexity on the quality of the print.

How design complexity impacts 3D printing time

Design intricacies can affect 3D printing times. Looking at data, we can see how design complexity affects printing time. For example:

| Design Complexity | Printing Time |

|---|---|

| Simple | 2 hours |

| Moderate | 5 hours |

| Complex | 10 hours |

It’s clear that design complexity has a big influence on printing time. Designers must keep this in mind.

By understanding the link between design complexity and printing time, designers can make informed decisions. This helps project managers and clients plan timelines.

In the past, designers used complex designs to create art. Technology has made 3D printing more advanced.

Designs can take longer to print, but explaining a delay to your boss is even more complex!

The effect of design complexity on the quality of the print.

Comprehending design complexity is key for successful 3D printing. A study by Roy et al., (2017) found that intricate designs with complex geometries can increase printing time. This could reduce print quality.

The table below shows the relationship between design complexity and the quality of print:

| Design Complexity | Quality of Print |

|---|---|

| Low | High |

| Medium | Moderate |

| High | Low |

Taking the right precautions when designing can help minimize printing time without sacrificing print quality.

Frequently Asked Questions

1. What factors affect 3D printing time?

There are several factors that can affect 3D printing time, including print speed, layer height, print volume, printer technology, and the complexity of the design.

2. Does increasing the print speed decrease the print time?

Yes, increasing the print speed can decrease print time, but it can also compromise the quality of the print. It’s important to find the right balance between speed and quality for each print job.

3. How does layer height affect 3D printing time?

Generally, thinner layer heights result in longer print times, while thicker layer heights can reduce print time. However, changing the layer height can also affect the quality of the print, so it’s important to consider the trade-offs.

4. Can the print volume affect 3D printing time?

Yes, the larger the print volume, the longer the printing time will be. This is because the printer needs to move across a larger area and print more material, which takes more time.

5. What role does printer technology play in 3D printing time?

The type of printer technology can affect the printing time. For example, some printers may use multiple nozzles or advanced materials that can speed up the printing process. However, these printers may also be more expensive or require more maintenance.

6. How can I reduce 3D printing time?

To reduce 3D printing time, you can adjust settings like print speed and layer height, optimize the design for faster printing, or use a printer with faster printing capabilities. However, it’s important to balance speed with print quality to ensure the final product is satisfactory.