Contents

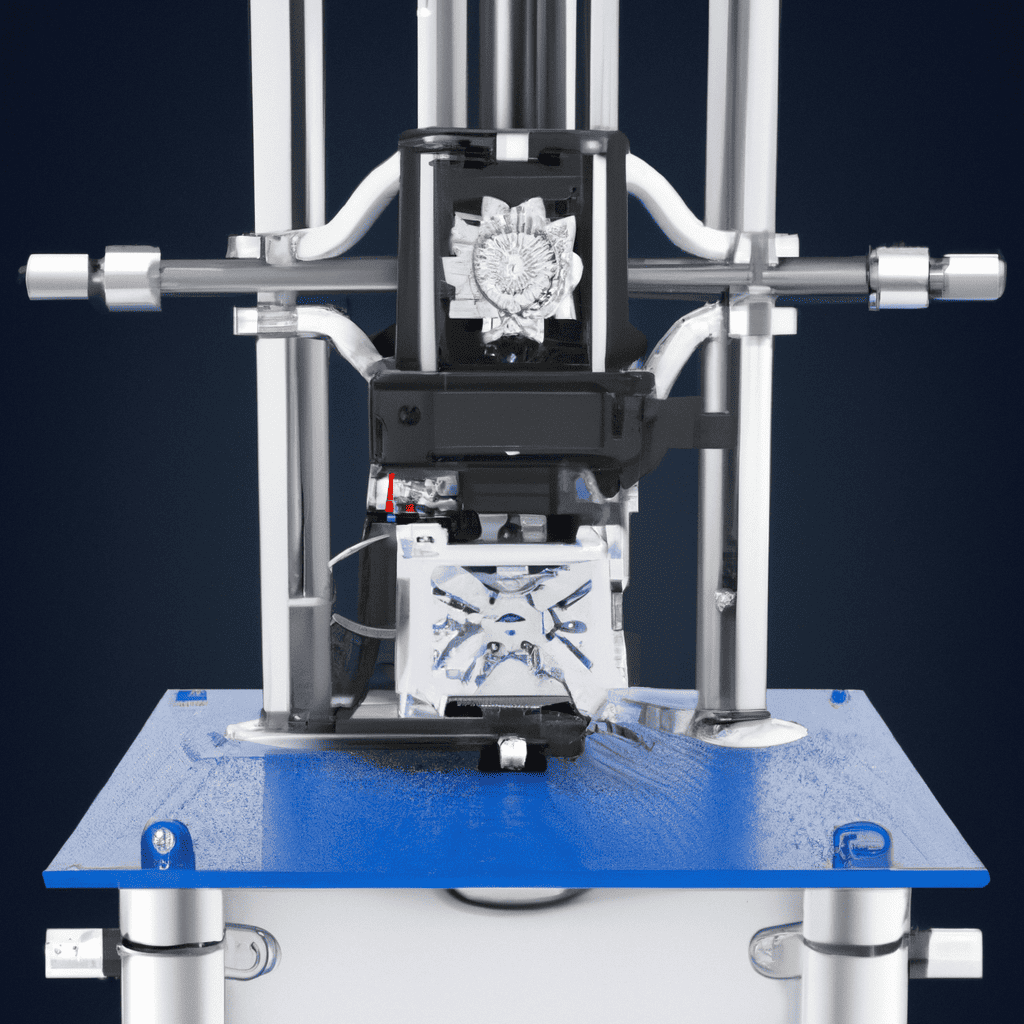

Understanding Ender 3 Y-Axis Problems

To fix and upgrade Ender 3 Y-Axis issues, knowing common troubles and the importance of proper alignment in 3D printing is crucial. Get a detailed understanding of the section – ‘Understanding Ender 3 Y-Axis Problems’ featuring two sub-sections, ‘Common Y-Axis Issues in Ender 3’ and ‘Importance of Y-Axis Alignment in 3D Printing’.

Common Y-Axis Issues in Ender 3

Sometimes the Y-Axis of Ender 3 can cause print quality issues. Let’s take a look at some of these problems and how to solve them.

For Skewed Print Bed: Re-assemble the bed correctly.

For Inconsistent Layer Height: Level the printing surface.

For Loose Belt: Tighten the belt.

It is important to do routine maintenance to prevent further problems. If not, it could cost you a lot in replacements.

Y-Axis Problems require special attention. Don’t ignore them or you may damage your printer.

Did you know that originally, the Ender 3 guide recommended using masking tape? It wasn’t until later that Creality released its own adhesive sheets, which are now widely used.

Don’t let your Y-axis issues get out of control- otherwise your prints could turn out looking like a chaotic rollercoaster!

Importance of Y-Axis Alignment in 3D Printing

A precise Y-axis alignment is essential for successful 3D prints. Its movement along the horizontal axis during printing depends heavily on its positioning. Deviations from accuracy can lead to issues like under/over extrusion, bed leveling problems and nozzle clogging.

To ensure accurate 3D prints, it’s important to regularly check the Y-axis of your printer. Misalignment compromises precision and can cause prints to fail. It can also increase wear and tear on parts like bearings and belts.

Regularly calibrate your 3D printer and check all maintenance requirements. This will extend its lifespan by decreasing stress on critical parts.

Pro tip: When checking your Y-axis, make sure the bedding surface is leveled and the material has the right properties. Solve Y-Axis problems like Sherlock Holmes with these diagnostic tips!

How to Check and Diagnose Y-Axis Problems

To diagnose and fix Y-axis problems in your Ender 3 3D printer, you’ll need a step-by-step guide for diagnosis and the right tools and techniques. In this section, we’ll explore these solutions in detail. The sub-sections will cover the step-by-step guide for Y-axis diagnosis, and the tools and techniques used for Y-axis diagnosis.

Step-by-Step Guide for Y-Axis Diagnosis

This article presents a clear and comprehensive tutorial for recognizing and solving Y-axis issues. Steps to diagnose the problem and get the printer running are listed below:

- Examine the Axis: Check for any signs of damage, like bends, cracks, or wear marks.

- Inspect the Belt: Look for fractures, breaks, tears, or loss of tension.

- Clean: Wipe off dust and debris in components like rails and bearings.

- Adjust Tension: Make sure the right belt tension is secured for optimal performance.

- Check Motor: Make sure your motor is active during synchronization with other parts, like pulleys and anchor points.

- Replace Parts: Switch out old components like bearings and worn-out belts for better results.

It’s vital to be aware of any sound changes or machine issues. Routine maintenance can also help prevent Y-axis troubles.

G-code is seen as an extra layer on top of an STL file, which usually matches up nicely. Get ready to troubleshoot your Y-axis with the best tools around!

Tools and Techniques Used for Y-Axis Diagnosis

To diagnose Y-Axis problems, certain tools and techniques are used. These help identify issues with precision. Software and hardware tools check the accuracy of movement along the Y-Axis.

The following table lists some essential tools and techniques used for Y-Axis issues:

| Tools | Description |

|---|---|

| Precision Level | Checks if the Y-Axis is level or sloping |

| Dial indicator | Detects defects or wear in bearings, screws, or rails |

| Laser Level | Verifies flatness with measurements |

| Edge Detector | Evaluates movements and vibrations |

More advanced analysis is possible with additional devices.

Besides these techniques, one should also check for any errors on the control panel screen. This indicates any flaws in position feedback systems like encoders attached to motors via controllers.

Pro Tip: It’s best to seek professional guidance while checking Y-Axis issues. Upgrade your Ender 3 Y-axis and give your printer a performance boost. No one likes a slow and underperforming printer (except your enemies).

Upgrading Ender 3 Y-Axis for Better Performance

To upgrade and fix Ender 3’s Y-Axis alignment issues for better printing performance, check out the following sub-sections: Types of Ender 3 Y-Axis upgrades, Comparison of Different Y-Axis upgrade options, and Step-by-step guide for Ender 3 Y-Axis upgrade. These will provide solutions and expert recommendations for a successful upgrade and optimization of your Ender 3 3D printing machine.

Types of Ender 3 Y-Axis Upgrades

When it comes to improving your Ender 3 Y-Axis, there are lots of upgrades available. These can help make your printer better in performance and functionality.

Evaluate your needs before making any changes. There are adjustable tensioners or those that use a spring mechanism for belt tensioner upgrades. Linear rails replace stock bearings with high-quality linear guides, improving stability in bed movement.

Stepper motor upgrades offer greater motion control and precision. Bed springs provide extra stability by ensuring optimal bed leveling.

A friend said his linear rails upgrade made his prints sturdier and sleeker. This proves why upgrading your Ender 3 Y-Axis should not be postponed – it’ll make a major difference in performance! Upgrade now and leave the competition behind.

Comparison of Different Y-Axis Upgrade Options

To help you make an informed decision, we’ve tabulated the data of various Ender 3 Y-axis upgrade options. Check out the table below!

| Upgrade Option | Price | Compatibility | Ease of Installation | Overall Performance Increase |

| Metal Extruder Kit | $25-$50 | Ender 3/Pro/5 Plus/CR-10S Pro, etc. | Easy install in under an hour. | Smooth filament feeding, less clogging and better extruder motor performance. |

| Belt Tensioner Kit | $15 – $20 | Ender 3/Pro/5 Plus/CR-10S Pro, etc. | Easily hooked around the belt and secured with a screwdriver. Takes 15 minutes max for installation. | Tights the belt for Y-axis limit switch and print accuracy improvements. |

| ZL Tech Metal Hotbed Spring Leveling Kit | Less than $15 / parts required for DYI kit or can be purchased pre-assembled online for up to $50 | Ender 3 (all versions) /Ender 2/Ender4/Cr-10s/S4/S5/Cr-10 mini printers only. | Quick-installation, bolts underneath the print bed. | Upgraded springs help restore and maintain a level print bed, essential for achieving the best prints. |

The Metal Extruder Kit and Belt Tensioner Kit are popular upgrades. But the ZL Tech Metal Hotbed Spring Leveling Kit is also a good choice. It’s important to make sure the upgrade is compatible before taking the plunge.

So go ahead, upgrade your Ender 3 Y-axis for better prints and specs! And if you mess up, just ‘Y’ not try again?

Step-by-Step Guide for Ender 3 Y-Axis Upgrade

Fancy an upgrade for your Ender 3’s Y-axis? Here’s a step-by-step guide!

- Assemble the new tensioner and bearings. Remove the old ones, place the new ones, and secure them.

- Mount the motor on the aluminum beam. Unfasten and shift it up.

- Remove the cable chain bracket from the bed’s right side. Reattach it to the top of the rail with zip ties.

It’s also wise to adjust belt tension after upgrading.

Do note that such modifications may void any warranties and that safety is of utmost priority – so, don those gloves!

3D printing aficionados have seen their humble builds become professional-grade masterpieces with these simple tweaks. No degree in engineering needed – just patience and a few YouTube tutorials!

Fixing Common Y-Axis Problems in Ender 3

To fix common Y-Axis issues in your Ender 3 printer, you need to troubleshoot Y-Axis skewing issues and resolve Y-Axis layer shifting problems. Skewing issues may cause your prints to be skewed, whereas layer shifting problems may lead to horizontal shifts in your print. In this section, we will discuss these two sub-sections as solutions to upgrade and fix your Ender 3 Y-Axis issues.

Troubleshooting Y-Axis Skewing Issues

Y-Axis movement complications? Troubleshooting is the key!

Here’s a 3-step guide for resolving Y-Axis skewing:

- Check belt tension and adjust if needed.

- Make sure Y-Axis wheels are correctly aligned, not loose.

- Examine motor coupling and thread engagement.

Lubricant or switching parts may come in handy too. Routine maintenance is a must for the best performance.

Troubleshooting is a must for any printer, no matter its model or make. An Ender 3 enthusiast noticed improved printing success after working through minor complications.

Let’s strive for smooth Y-Axis movement and flawless 3D prints!

Resolving Y-Axis Layer Shifting Problems

Got layer shifting issues in your Ender 3 printer? Don’t worry! Here’s a guide to help resolve these problems:

- Check the belt tension. Make sure it’s tight enough to stop slipping.

- Lubricate the Y-axis gantry bearings and rods for smoother movement.

- Inspect and tighten all screws and bolts related to your printer.

- Confirm the bed is level. Inconsistent filament adhesive can cause layer shifting.

- Check your power supply voltage. Unsteady voltage causes under-extrusion and irregular motion.

- Reset your slicing software settings and any calibrations.

If none of this works, contact professional service staff.

Important: Don’t put too much weight on a glass bed when screws are loose. This will make it hard to get the right level. Also, try upgrading the components to get better adhesion.

Conclusion: Give your Ender 3 Y-Axis some TLC and you’ll get smooth printing results and avoid misalignments that cause errors in horizontal layers.

Maintenance and Care Tips for Ender 3 Y-Axis

To ensure that your Ender 3 3D printer is running smoothly, in order to avoid any Y-axis problems, turn your attention to the Y-axis maintenance and care tips. A couple of sub-sections namely Cleaning and Lubricating Ender 3 Y-Axis and Preventive Maintenance Techniques for Ender 3 Y-Axis provide solution to keep your Y-axis in proper alignment and improve the longevity of your 3D printer.

Cleaning and Lubricating Ender 3 Y-Axis

When caring for your Ender 3 printer, it’s important to keep the Y-Axis clean and lubricated. This enables the bed to move easily and precisely during printing, leading to better results.

To grease and clean your Ender 3 Y-Axis, follow these steps:

- Switch off the printer and unplug it.

- Clean the Y-Axis rail with a cloth or brush to remove dust and debris.

- Put a bit of grease or oil (like PTFE) on the rail. Don’t use too much, as it can attract dust and dirt.

- Wipe away any excess with a clean cloth.

- Move the bed back and forth to spread the lubricant.

- Plug in and switch on the printer. Move the bed manually to check it slides smoothly before resuming printing.

Remember, too much lubricant can spoil prints. Clean the Y-Axis regularly to avoid dirt, debris, and dried-up grease, prolonging its life and making sure it runs properly. Keep your Ender 3 Y-Axis in top condition for smooth sailing!

Preventive Maintenance Techniques for Ender 3 Y-Axis

To keep your Ender 3 Y-Axis going strong, preventive maintenance is key! Regular checkups and maintenance guarantee smooth operation in the long run. Here are six simple steps to maintain your Ender 3 Y-Axis:

- Wipe it Clean – Clean the Y-Axis with a damp cloth every week.

- Lubricate – Add lubricant to all sliding parts, to reduce friction and wear.

- Belt Tension – Adjust the belt tension as per requirement.

- Belt Replacement – Replace the belt if any damage is visible.

- Bed Leveling – Level the bed on which the printer rests.

- Bed Temperature – Set the bed temperature according to what you’re printing.

Do these steps regularly to keep your Ender 3 Y-Axis in tip-top shape. And don’t forget to use quality parts and materials when building! Doing so will improve print quality, as well as extend its lifespan. So, forget about ‘why-are-my-prints-so-jumpy’, and start experiencing smooth Y-axis performance with these maintenance tips.

Conclusion – Achieving Optimal Y-Axis Performance in Ender 3

To get the most out of your Ender 3, Y-Axis Precision is key. The Y-Axis holds the hotbed, meaning it needs to be in check.

Upgrading the belt tensioner, replacing bearings, and rewiring connections are essential to improving Y-axis performance.

Also, check the tightness of the eccentric nut to stop wobbling and yield high-quality prints. And, don’t forget to lubricate sliding parts to keep them in action for a long time.

Don’t miss out on getting the best prints from your Ender 3 by overlooking Y-axis issues. Take action and upgrade, fix, and optimize it for optimal performance.

Frequently Asked Questions

1. What are some common Y-axis problems with the Ender 3 3D printer?

Some common Y-axis problems include misalignment, skipped steps, and excessive noise or vibration during printing.

2. How can I fix misalignment issues with the Y-axis?

You can fix misalignment by adjusting the position of the Y-axis tensioner, checking that the belt is properly tensioned, and ensuring that the Y-axis motor is securely mounted.

3. How do I identify skipped steps in the Y-axis?

You may notice that the printer is not printing accurately or consistently, or that the print bed is shifting during printing. You can also try running a test print and checking for any missed layers or gaps in the print.

4. What upgrades can I make to the Y-axis to improve performance?

You can upgrade the Y-axis with a sturdier and more reliable motor, a reinforced base plate, and a high-quality belt and tensioner system.

5. How do I install a new Y-axis motor?

You will need to remove the old motor, carefully install the new motor, and then adjust the belt tension and alignment to ensure proper functioning. Refer to your printer’s manual or online tutorials for specific instructions.

6. Can Y-axis problems be caused by issues with other components or settings?

Yes, Y-axis problems can be caused by issues with the printer’s overall calibration, power supply, or firmware. It is important to troubleshoot and address these issues before attempting to upgrade or fix the Y-axis.