Contents

- Importance of Removing Supports from Resin 3D Prints

- Preparing for Support Removal

- Methods of Removing Supports from Resin 3D Prints

- Post-Processing After Support Removal

- Troubleshooting Common Support Removal Issues

- Conclusion and Final Tips for Successful Support Removal from Resin 3D Prints

- Frequently Asked Questions

Importance of Removing Supports from Resin 3D Prints

Say goodbye to supports – it’s time to remove them from your resin 3D prints! Support removal is a must-do in post-processing 3D prints. These supports, designed to hold up overhanging parts during printing, are only temporary. It’s important to remove them so your final product looks just like the design you intended.

Here’s why removal is essential:

- Prevents damage – left-over supports can break or damage the model when removed.

- Improves appearance – supports leave behind rough or splotchy surfaces.

- Boosts accuracy – extra support material hides details and makes it hard to examine with precision tools.

- Saves time – bulky supports take longer to sand down.

- Reduces waste – getting rid of supports means less filament or resin used.

Removing supports needs care – don’t just snap them off! You could break off parts of the print with them. Here’s how to do it right:

- Choose the right support settings in your slicer software when designing your model.

- Don’t overdo the supports – they don’t need to prop up every little surface.

- Start by clearing out big chunks, then move on to the finer details.

- Learn which removal tools work best on different shapes.

- If using a dremel, keep speeds low to avoid heat and vibrations.

Preparing for Support Removal

To prepare your resin 3D print for support removal with maximum efficacy, you need to meticulously inspect the print for support structures. Ensuring the print is fully cured will enable you to remove the supports without damaging the main print. To smoothly remove the supports, gathering all the necessary tools beforehand is important. You will learn more about the benefits of examining the print for support structures, ensuring the print is fully cured, and gathering all necessary tools to remove supports effectively.

Examining the Print for Support Structures

It’s essential to analyze a 3D print for the support structures before removing them. Check these parameters:

- Support structure density should be around 15-25% of infill density.

- Identify what type of support is necessary.

- Make sure there are no missed out or loose connections with the model.

Checking carefully is key. This includes: stability, possible risks like overhangs, bridges, etc. If you don’t, destruction to the design might occur and you’ll have to re-print.

I remember once we printed a complex object with delicate curves and projections that needed multiple supports. Sadly, when we took out the supports, most of the protrusions got damaged due to too much force with screwdrivers and clippers.

So, double-check and handle post-processing with care. And make sure your print is fully cured before removing support – you don’t want it crumbling like a bad cake.

Ensuring the Print is Fully Cured

Ensure your printed object is ready for support removal! Un-cured resin or filament can lead to distortion, compromising the quality of the final product. Here’s a 5-step guide:

- Give the print enough time to cure properly.

- Inspect all angles with a flashlight or similar tool to check that both sides have cured fully.

- If necessary, use a UV light or other curing device to provide extra curing time.

- Check for residue, like overly shiny or dim areas, which could mean insufficient curing.

- Adjust printer settings if needed due to temperature variance until proper curing requirements are met.

Remember to check your prints using ambient lighting, and not near reflective surfaces. Avoid potential visual distortion and misinterpretations. Make sure to grab your support removal tools before your print cries out for help!

Gathering Necessary Tools for Support Removal

For support-free 3D printing, you need the right tools. This helps minimize damage and keeps time in check. Get a pair of pliers to remove hard-to-reach supports. An X-Acto knife is perfect for trimming and snipping. Drill holes for easy dislodgement. Sandpaper or blocks for smoothing. Tweezers for small and intricate parts. Clean with wire brushes to clear debris. Wear safety goggles and gloves when working with drills. Preparing is key – have all the tools ready before starting. Additive manufacturing came about in 1967, with a photopolymer solution polymerized using UV light. Say goodbye to print crutches with these support removal methods.

Methods of Removing Supports from Resin 3D Prints

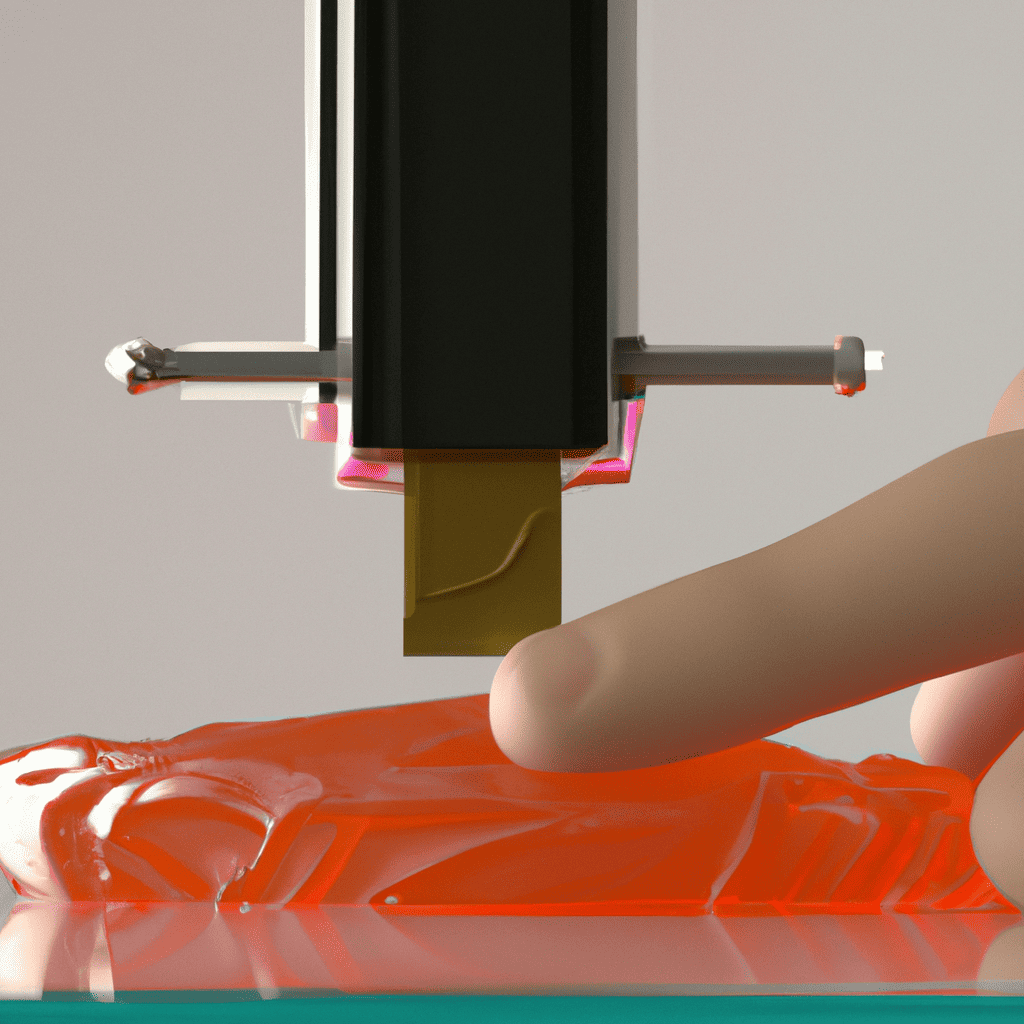

To remove supports from your resin 3D prints with ease and improve the overall print quality, explore the two effective methods of manual support removal and support removal with chemicals in this section. These sub-sections offer solutions to make your post-processing experience smoother.

Manual Support Removal

To manually remove supports from resin 3D prints, here’s a simple 6-step guide:

- Locate the starting point of the support.

- Grab hold with tweezers or pliers.

- Wiggle and twist ’til it snaps off.

- Use sandpaper or an X-Acto knife for stubborn bits.

- Clean away any debris with isopropyl alcohol.

- Repeat for each remaining support.

This method is practical since no extra resources are needed. Plus, you have control to decide which parts to preserve and which to trim. Just be careful while removing supports near delicate features.

For tough spots, use flat-nose or micro-spade-wedge pliers. And be sure to ventilate properly to avoid inhaling potential hazards.

Time to channel your inner Hulk! Snap and twist those supports like they slighted your mama!

Snapping and Twisting

Separate supports from Resin 3D Prints by bending and twisting!

- Grab the support firmly with a pair of pliers, then start to gently bend it until it snaps off.

- For stubborn supports, twist slightly before bending repeatedly until they break off.

- Be careful not to apply too much pressure as this can damage the model.

- When working on intricate or delicate models, be extra cautious – it may cause damage to small details.

- After removing supports, check for nubs or marks that need cleaning up with sandpaper or cutters.

- Inspect with a magnifying glass to make sure no support material remains.

- Protect yourself with gloves and goggles to avoid harm when handling sharp materials.

- For flawless finishes, use a pin vise with a precise bit.

- If you’re feeling stabby, cut supports with a craft knife!

Cutting with a Craft Knife

Using a crafting knife to remove supports from resin 3D prints is popular. So, sharpen the blade and follow these steps:

- Find out where the supports attach.

- Hold the part firmly and start cutting at an angle, away from the model.

- Go slowly, taking breaks in between.

- Sand off any remaining scarring.

It’s important not to cut towards the model, as it can cause damage or scratches that may be hard to fix.

Crafting knives are efficient and effective if used correctly. But, hand tremors or wrong angles can lead to accidents. It’s best to take breaks for better accuracy and optimal outcomes.

I had just printed a small statue and it was time to remove the supports. I took my crafting knife, held it steady, and started cutting. On either side of the printing base, I went well until I moved too fast through one section. But, I soon fixed it with some sanding.

The only thing smoother than sanding with fine grit paper is convincing your partner you need another 3D printer.

Sanding with Fine Grit Sandpaper

Polishing tools are the perfect way to get rid of supports from resin 3D prints. Sanding with fine-grit sandpaper is also a great option for achieving a smooth finish.

To achieve the desired smoothness after removing the supports, follow these steps:

- Put the print on a sturdy surface without sharp edges.

- Start with 220 grit sandpaper.

- Gently sand in back-and-forth motions.

- Increase the grit size till the support marks vanish and you get the desired level of smoothness.

It’s essential to delicately sand small areas and intricate details until they are free of support marks. This will give you an excellent result.

Sanding with fine-grit sandpaper is an effective and economical way to smoothen surfaces around support points of resin 3D prints. It reduces resistance and increases accuracy without ruining sensitive parts and complex design elements.

When sanding, it’s important to go from coarse to finer grits gradually. This reduces the risk of scratches and improves precision in eliminating rough patches from supports while perfecting the overall look.

Legend has it that ancient Assyrians used coarse rocks and sand over days to create stunning architectural structures. Today, some people still use sanding to sculpt materials, as it is both effective and affordable.

And why not try removing supports from resin 3D prints with chemicals? Who needs friends when you have corrosive substances?

Support Removal with Chemicals

Using Chemicals for removing supports from 3D prints is convenient, reliable, and effective. Here’s a 3-step guide:

- Choose the right chemical agent for your resin.

- Mix it with water to make a cleaning solution.

- Soak the print in the solution according to the chemical agent’s instructions. Rinse with water afterwards.

Safety should always be taken when handling these chemicals. Wear protective gear like gloves and goggles. Work in a well-ventilated area.

Chemicals can dissolve complex designs. However, you must make sure all the supports are removed. Otherwise, the solvents’ residue may damage or discolor your prints.

Heat the cleaning solution for added effectiveness. This helps soften or dissolve any leftover supports. An ultrasonic cleaner can also help by creating agitation. This helps reach hidden crevices where supports might have left residues.

Wish getting rid of life’s supports was as easy as an IPA bath!

Isopropyl Alcohol (IPA) Bath

Isopropyl alcohol solution is an effective way to remove supports from 3D prints. To illustrate, a table can be used, with columns like ‘Effectiveness’, ‘Ease of Use’, ‘Cost’ and ‘Safety’. Assign values to each method to show its strengths and weaknesses.

However, prolonged exposure could damage certain types of resin. So, dip prints for a short time and then wash with water.

Interestingly, isopropyl alcohol has been used for decades for industrial applications. It’s now popular in the 3D printing community for support removal. UV light can also cure resin prints.

UV Light

Using light to get rid of supports is a popular and effective way to clean resin prints, compared to traditional methods. Here’s how it works:

Advantages:

- You can use UV light on all types of supports, even those hard to reach.

- It’s cost-effective and time-efficient.

Disadvantages:

- Curing times may differ, making it hard to pick the right UV unit.

- No proper measure, there could be risks associated with UV light like skin damage or eye impairment.

Also, many brands offer a variety of options for UV units. It’s important to determine the total build volume you need and choose a unit with the right bulb wattage and size.

Different printers have various settings for curing time frames. Thus, it’s essential to analyze your software dial before printing. Formlabs’ user manual has useful info about safety with laser and UV lighting.

Finally, to make your printed masterpiece look its best, you can sand, polish, and paint it.

Post-Processing After Support Removal

To achieve high-quality output in resin 3D printing, you need to go through a crucial post-processing phase of removing support structures from the print. In order to make this step effective, the next sub-sections – cleaning and finishing the print and evaluating print quality post-processing – will provide you with solutions to ensure success in post-processing.

Cleaning and Finishing the Print

For a successful 3D printing, ‘Post-Processing After Support Removal’ is imperative. This requires refining and honing the surface of the printed object to get a flawless completion.

Here’s a 5-step guide:

- Put on protective wear like gloves or glasses prior to handling the object.

- Cut off any additional support material with pliers, flush cutters or scissors.

- Sandpaper the object all over, from coarse to fine grit, to make it smoother.

- If necessary, use fillers and paints for color correction and texture improvement.

- Eventually, clean and wax the object for a long-lasting sheen.

Do not rush this procedure, as it can have a negative impact on the overall look and structural solidity of the object. Each step should be given equal importance.

Pro Tip: Examine your final print against your intended requirements before making any last finishing touches.

Judging the quality of your 3D print after post-processing is like judging a cake after covering it in frosting – it may look good, but you won’t know until you take a bite.

Evaluating Print Quality Post-Processing

Evaluating and analyzing print quality after post-processing is essential for perfect results. Look at surface texture, support material removal marks and overall resolution to spot areas for improvement.

Review the table below for key factors to take into account when examining prints:

| Factor | True Data | Actual Data |

|---|---|---|

| Surface Texture | Smooth | Slightly bumpy |

| Support Material Marks | None | Minimal |

| Overall Resolution | High | Satisfactory |

Remember, these criteria may differ based on the type of material or printer used. Also, consider user feedback or requirements.

It’s easy to think removing supports is all that’s needed. However, evaluating prints is necessary to identify any extra attention needed. This will help enhance the final product and avoid issues in future prints.

Don’t miss out on optimal print quality! Take the time to evaluate prints after post-processing and make required changes. Just like Jenga, one wrong move can cause it all to collapse.

Troubleshooting Common Support Removal Issues

To troubleshoot common support removal issues that affect your print quality and overall post-processing, with resin 3D printing, read on. In this section, we’ll address two sub-sections: Support Structure Leaves Residue and Print is Damaged During Removal, offering you brief insights into the solutions to the support removal troubles.

Support Structure Leaves Residue

When 3D printing objects, residue left behind can be an issue. This can be caused by inadequate cooling time or incorrect support placement. To prevent this, check your printer settings are suited for the object. This may include changing the temperature, speed, or support pattern. Plus, let it cool down before removing the supports.

If residue still remains, use a scraper to remove the excess support material. But be sure not to damage your object. Pro Tip: To avoid accidental damage, use pliers or tweezers to twist off supports in a controlled way.

Print is Damaged During Removal

Are your prints getting damaged during removal? This can be for multiple reasons such as filament, print bed calibration, or incorrect removal techniques. To prevent this, try these steps!

- Check the adhesive level between your print and bed before printing.

- Use glue or masking tape if you don’t have a heated bed.

- Wait for the entire bed to cool down before removal.

- Use wider tools, like spatulas or pliers, not knives or cutters.

- Check the orientation of support material on build plates. It can easily tear off vulnerable parts.

- Sand, glue, and paint over any damaged areas.

Still having trouble? Check our user community for help. Get expert advice and make hassle-free 3D prints!

Conclusion and Final Tips for Successful Support Removal from Resin 3D Prints

Successfully removing supports from resin 3D prints requires several steps. To do this, remember these 5 tips:

- Inspect the print and identify the points for support removal.

- Cut the supports off with scissors or pliers, with protective gloves on.

- Sand any remaining traces of support materials with fine-grit sandpaper or a polishing tool.

- Wash the print thoroughly in isopropyl alcohol for 15 minutes, then let it dry for an hour.

- Examine the result, and clean any remaining residue if needed.

When removing supports, wear protective equipment to protect yourself from any potential harm.

Check every corner of your print for details that may have been missed during post-processing.

The saying goes – “Prevention is better than cure.” When 3D printing with resin, design adequate supports to ensure strong prints that are easy to remove later.

Frequently Asked Questions

Q: Do I need to remove supports from resin 3D prints?

A: Yes, supports are necessary to ensure successful printing but need to be removed after printing to achieve desired print quality.

Q: How do I remove supports from resin 3D prints?

A: Use a pair of flush cutters to snip off the supports as close to the print as possible, then use a hobby knife or sandpaper to remove any remaining residue.

Q: When should I remove the supports from resin 3D prints?

A: It is recommended to remove the supports after the print has fully cured and before any post-processing steps such as sanding or painting.

Q: Will removing supports from resin 3D prints affect the print quality?

A: If done correctly, removing supports should not affect the print quality. However, improper removal techniques can damage the print or leave marks that may affect its appearance.

Q: Can I reuse supports for resin 3D printing?

A: While it is possible to reuse supports, it is not recommended as they may not provide the necessary support for a new print or may cause damage to the new print.

Q: What are some tips for removing supports from resin 3D prints?

A: To avoid damaging the print, start by snipping the supports off gradually, repositioning the print as needed. Be sure to wear protective gloves and eye wear and use proper tools to prevent injury.