Contents

Understanding Warping and Curling in 3D Prints

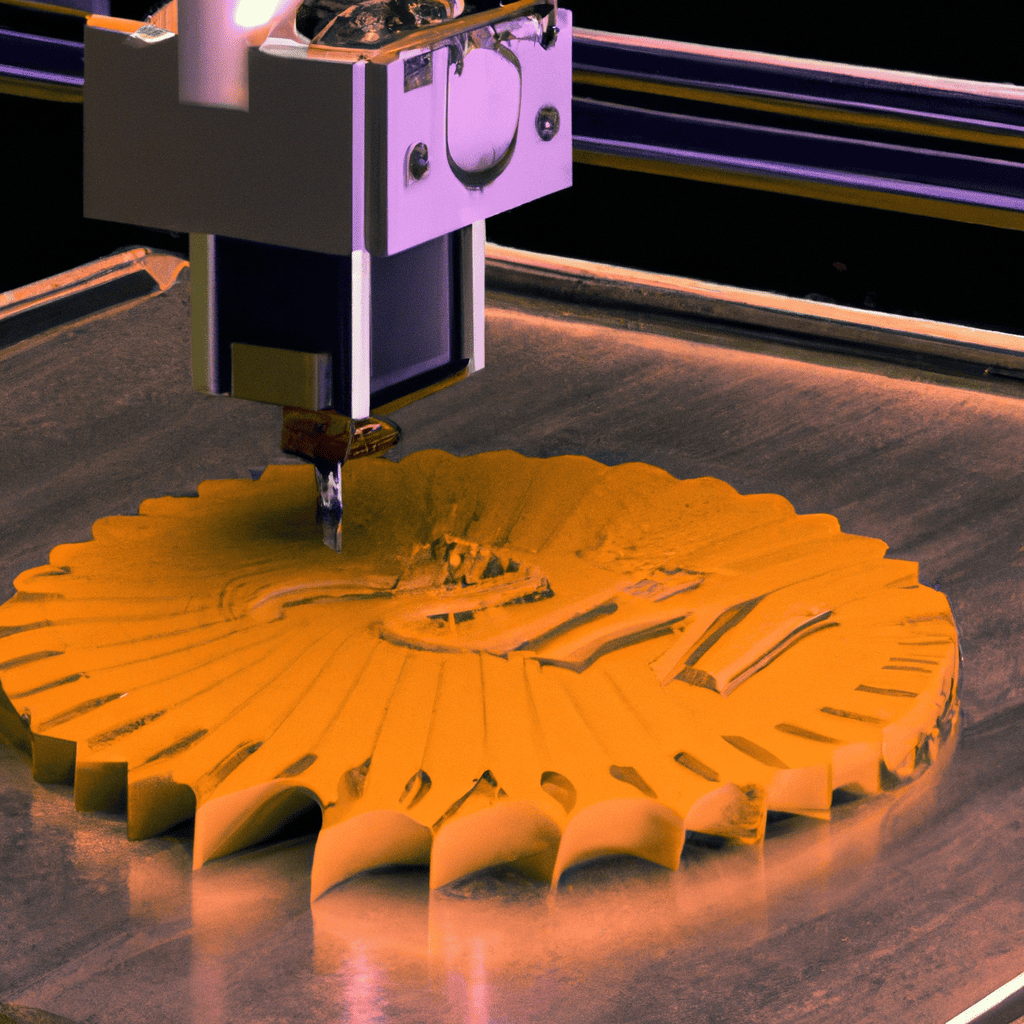

Sometimes 3D prints can’t handle the heat and pressure – warping and curling. Let’s explore why! Take a look at this table:

| Causes of Warping | Solutions |

|---|---|

| Poor Adhesion to Print Bed | Clean bed surface, use heated bed or raft/brim for printing. |

| Cooling too quickly | Reduce cooling speed or use a printer enclosure. |

| Inadequate Support Material | Use proper supports and make sure they’re connected. |

| Incorrect Printing Temperature | Increase temperature of print bed/nozzle according to material guidelines. |

Identifying the cause is essential. Unique factors include settings, materials, temperature and moisture content. Change your print settings, improve bed adhesion, use optimal printing conditions – prevent further damage. Don’t miss out on quality prints! Implement these solutions for great 3D creations.

Causes of Warping and Curling in 3D Prints

To understand why your 3D prints are warping or curling, this section with the title ‘Causes of Warping and Curling in 3D Prints’ with sub-sections as solution briefly explains the three main culprits: inadequate bed adhesion, incorrect printing temperature, and cooling issues.

Inadequate Bed Adhesion

Poor adhesion between the bed and filament can cause warping and curling in 3D prints. It weakens the object’s overall strength. To prevent this, clean and level the print bed before starting print jobs.

Adhesive sprays or tapes, higher bed temperature, increasing infill density, surface treatments like glue sticks or hairspray – these can all help improve bed adhesion. For uniform contact, ensure an evenly distributed layer. Also, remove prints carefully, without excessive force.

Experiment with materials and configurations for optimal results! Lastly, to avoid warped prints, check that your 3D printer is at the right temperature.

Incorrect Printing Temperature

Temperature is key for 3D printing. If it’s not optimized, the printed object can turn out misshapen. Temperature variation during printing leads to part warps and curls, which disrupts quality.

Create a table to track filament materials and the optimal heating level for each. Different materials require different temperatures. Printing range affects the build plate’s temperature. Nozzle temperatures increase consistency.

Table: Filament Materials and Recommended Heating Levels

| Filament Materials | Optimal Heating Level |

|---|---|

| PLA | 180-220°C |

| ABS | 210-250°C |

| PETG | 220-250°C |

| Nylon | 240-260°C |

| TPU | 200-230°C |

Unique parameters impacting temperature regulation include building size, cooling, raster angle, and semi-enclosed spaces. These all lead to uneven thermal distribution.

According to ‘IEEE International Conference on Industrial Technology’, ‘The print bed’s flatness and smoothness could also have an effect on warping’. Experimental setup is vital for achieving perfect printing pattern forecasts.

Time to crank up the AC – our 3D printer is having a hot flash!

Cooling Issues

Issues like warping and curling in 3D prints can be caused by cooling. The material used is heated and melted to create layers. Then, these layers cool and contract quickly, leading to deformity or shrinkage.

One solution? Utilize a heated bed to keep temperatures optimal and prevent rapid cooling. Plus, a closed chamber can provide insulation and minimize temperature changes.

Adjusting fan speed during printing can also help. Fans are usually used to cool the hotend, but too strong or too early can cause uneven cooling.

Remember, different materials have different cooling settings. So, always refer to manufacturer recommendations when changing printer settings.

Fixing Warped and Curled 3D Prints

To fix warped and curled 3D prints, you need to adjust your print bed settings, use an enclosed printer, turn up the heat, slow down printing speed, use a brim or raft, use a cooling fan, or use a print warping solution. These sub-sections are the solutions that will help you find the causes of warping in 3D prints, such as poor adhesion and incorrect temperature, and fix them effectively.

Adjusting Print Bed Settings

For better 3D print quality, adjusting the print bed is key. Here’s a pro tip on how to do it:

- Level the printing surface – no bumps or ridges.

- Measure the nozzle and build plate distance with a feeler gauge.

- Adjust z-offset settings if necessary, calibrating to an ideal distance.

- Re-calibrate if any changes have been made.

- Switch to a textured build plate for better adhesion.

Material type, printing temp, humidity, and cooling rate may affect warping and curling. So note them too!

Using textured plates can lower accuracy due to uneven pressure distribution.

Printer brands vary in how often bed adjustment is required. Know these variations to troubleshoot curled or warped prints.

Finally, a printer that can handle my warped and twisted humor – contained and enclosed, just like my prints!

Using an Enclosed Printer

Fixing warped and curled 3D prints? Get an enclosed printer! It helps maintain an even temperature. This means the filament melts evenly, avoiding warpage or curling. Some enclosed printers also have filtration systems to improve air quality. Remember to invest in one with enough space. 3D Insider says enclosed printers are essential for ABS and PETG materials that require high temperatures. Game-changer! Let’s get steamy and turn up the heat to fix those pesky prints.

Turning up the Heat

Heat can be used to fix warped and curled 3D prints. Apply hot air with a heat gun or hairdryer to affected areas only, not the entire print. Start with low heat and increase it gradually. Securely hold the print as you reshape it with gentle pressure until flat again.

For larger and more stubborn warps, try an oven at 55-65°C for a few minutes. Be cautious not to overheat! You can also try immersing the print in hot water at around 60°C for a few minutes before reshaping it while still damp.

Broken or cracked prints should not be fixed using this method, as it can damage weakened areas too much.

Pro Tip: Wear gloves when handling heated objects. Also, slow and steady printing speed is key for good-looking 3D prints.

Slowing Down Printing Speed

Slow Down for 3D Printing!

Do you have 3D prints that are warping or curling? To fix them, you may need to slow down the printing process. Here’s a 5-step guide to help:

- Open your slicing software

- Select “Print Settings” > “Speed and Flow” > “Print speed”

- Adjust the “Print speed” setting

- Consider altering layer height and extrusion rate

- Save settings and start the print job

Remember, slowing down the speed can improve print quality, but it’ll take more time than usual. Alternatively, you can try sticking adhesive surfaces or special coatings on your bed surface. These could reduce warping or curling without needing to slow down your printer.

For example, Kevin was having trouble with his 3D prints flattening out. He tried adhesives with no luck. Finally, he lowered the printing speed and his prints stuck better and finished without issue. For a sure-fire way to protect your prints from curling, try a brim or raft!

Using a Brim or Raft

To avoid warping and curling in 3D prints, you can use a Brim or Raft technique. This involves making a thin layer of filament around the base of the print. To better understand how to use Brim or Raft, check the table below. It has the variables related to temperature, material type and platform adhesion.

Variables:

- Brim – 5-10°C, PLA, Blue tape

- Raft – 15-20°C, ABS, Glass

- Skirt – 0-5°C, PETG, Perf board

Though applying a raft or brim can fix many warped prints, it is not always necessary. If dealing with intricate prints or an unusual shape, you can add supports or change the orientation of your part before printing.

Funny enough, this trick has been around since ancient times. People used it in furniture making to prevent warping.

Bring your 3D prints back to life with a cooling fan! This will help them get rid of their warped and twisted ways.

Using a Cooling Fan

Say goodbye to wonky prints and hello to flat perfection! Implement a strategy for reducing 3D print temperature post-deposition using a cooling fan. Place a fan close to the printing space for an immediate contactless cooling effect. Increase the fan speed as more material is extruded. Position the fan to evenly cool the entire print bed. If additional cooling power is needed, use two or more fans operating in tandem. Explore pre-programmed settings on the software and test fan intensities.

Cooling fans work best when combined with proper bed adhesion techniques, material selections, elevated platform temperatures, and optimal room temperatures. Monitor temperatures during printing to avoid difficulty with the print job. Check vendor web pages for guidelines on fragile components’ optimal temperature ranges, and make necessary alterations. Practice these techniques regularly for faultless results every time!

Using a Print Warping Solution

To prevent warped and curled 3D prints, one can use a technique that adjusts various factors. These include:

- temperature (raised for better layer bonding and less contraction),

- cooling (reduced or eliminated to avoid shrinkage and warpage), and

- adhesion (ensured via appropriate materials, settings, or adhesives).

Also, optimal printer conditions must be maintained. This includes proper calibration, cleaning the build plate, and regular maintenance checks.

For improved solutions, it is advised to use a heated build platform or an enclosed printing environment. The former allows for optimal layer bonding by heating the area underneath the object. The latter creates a stable environment by reducing temperature fluctuations and air currents that cause cooling or heating.

To avoid warping and curling in 3D prints, prevention is key, unless you’re aiming for a Salvador Dali look!

Tips to Prevent Warping and Curling in 3D Prints

To prevent warping and curling in your 3D prints, follow these tips in “Tips to Prevent Warping and Curling in 3D Prints” with solutions such as using the correct bed surface, maintaining proper printing temperature, using good quality filament, calibrating your printer regularly, using support material when needed, rotating the model before printing, and reducing printing time by using thicker layers.

Use the correct bed surface

Choosing the right bed surface for your 3D prints is essential. Here are some tips to consider:

- Opt for a smooth surface. This will help prevent warping and curling.

- Choose build surfaces that don’t require heat. This will prevent uneven cooling and warping.

- Textured surfaces, such as BuildTak or PEI sheets, can provide great grip. But be careful not to cause unwanted deformations.

- Use the right adhesion method. Too little or too much bond between bed surface and first layer of filament can be bad.

- Adhesive products should be used sparingly. Too much can lead to residue buildup.

Keep these tips in mind and invest in multiple bed surfaces for different materials or prints with specific adhesion requirements. Also, make sure your printer stays hot to avoid warped and curled 3D prints.

Maintain proper printing temperature

Maintaining the correct printing temperature is key for successful 3D prints. Here’s how:

- Check your printer’s manual for the correct temperature settings and confirm they match the filament you’re using.

- Monitor your printer during use and make adjustments as needed.

- Use a heat-resistant surface or enclosure to avoid external factors.

Incorrect temperatures can disrupt layer adhesion, resulting in warpage and curling. Keep the temperature consistent for smooth, high-quality prints. Don’t forget this step! Without it, your print won’t look as good. Cheap filament with improper temps is a recipe for disaster.

Use a good quality filament

Opting for superior quality filament is essential to prevent warping and curling in 3D prints. Low-grade filaments can result in weak layer adhesion and inconsistent material flow, which causes the final print to warp or curl. Consider the below steps for using high-quality filaments:

- Select a reliable supplier who offers premium filaments.

- Inspect the moisture content before use, as it can affect the print quality.

- Choose filaments with consistent diameters for smooth printing.

- Stay away from expired or aged filaments.

- Customize printer settings as per the filament used, for accurate results.

- Preserve the filament in an airtight container, with dehumidifiers if needed, to keep out moisture.

There are more elements to consider while selecting superior quality filaments. Make sure the raw materials used by the manufacturers have consistent chemical composition. This helps in avoiding over-extrusion or under-extrusion of raw substance during printing.

Using inferior quality filaments is not only disheartening; it often does not give the desired outcome. A buddy of mine purchased cheaper filaments and saw that they did not stick properly, resulting in incomplete prints. Despite doing repeated refits and adjustments at spaced out areas of his print surface, his sectioned parts couldn’t be fitted together due to poor interconnections. His conclusion was straightforward — spend well now for long-term benefits later —and he has since changed production methods by picking high-quality 3D filaments with better structural stability metrics.

Cryptography may seem complex initially but can be deciphered with effort.

Keep your printer working flawlessly by calibrating it frequently – unless you want your prints to resemble a cat’s fur after a fight with a hairdryer.

Calibrate printer regularly

Calibrating your 3D printer is essential for success with your prints. It helps fight warping and curling. Here are the 3 steps:

- Check the bed level. Adjust it if needed, depending on the surface.

- Calibrate the extruder. Check and adjust the temperature.

- Clean the print bed. This ensures good adhesion and no warping.

Do this regularly. It will give you top-notch results.

You should also use good quality filament and don’t over-extrude.

Temperature, ventilation and humidity are all important too.

And don’t forget the support material to stop the filament going all noodly.

Use support material when needed

When printing 3D models, support material may be needed depending on the complexity. These supports prevent warping and curling during printing. Without them, layers could get detached, leading to distorted prints. Knowing when and where to place them can have a big effect on the final product’s quality.

It’s also important to understand different types of support materials. Water-soluble ones work great for complex designs that need detail. Removing them is simpler and faster than non-soluble ones like breakaway supports.

Pro Tip: Use support material only when necessary. Excess material can take up too much post-processing time. Change the direction of your print by rotating the model. This can help avoid warping and curling.

Rotate the model before printing

To avoid warping and curling of 3D prints, it’s important to consider the orientation of the model before printing. Correctly rotating the model ensures even cooling and filament distribution – leading to high-quality prints and fewer failures. Here are four steps to rotate the model before printing:

- Import STL file into the slicing software.

- Preview the model – check any overhangs or unsupported areas.

- Use the rotation tool to adjust the orientation of the model for optimal support.

- Save the edited settings and start the print job.

Leveling the printer’s bed also helps prevent warping. However, rotating models can affect structural strength – keep aesthetics and durability in mind.

To avoid delays, material costs and additional workload, follow these tips when rotating models before printing. Thick layers reduce printing times, but at the cost of detail. Beauty is pain!

Reduce printing time by using thicker layers

Printing with thicker layers can speed up the printing process. But, it’s important to be careful with the quality of the final product. To do this, you might need to make slight changes to variables such as nozzle size, layer height, and extrusion multiplier.

Here are 5 ways to reduce printing time by using thicker layers:

- Adjust Layer Height: A 40% increase from 0.2mm to 0.28mm will cut printing time by half.

- Make Sure Filament Adheres Properly: Poor adhesion leads to under-extrusion or too much material.

- Change Printing Speed: Going too fast can result in stringing and inaccuracies.

- Analyze Nozzle Configuration: A bigger nozzle lets out more material per stroke.

- Fine-tune Extrusion Settings: Adjustments can improve flow and reduce cooling times.

For even more optimization, try increasing infill density or tweaking support structures. Thicker layers can also create stronger prints, reducing warping. However, too many modifications may mean details are lost.

Back in the day, artisans used tools to carve intricate designs into materials like bronze or iron. Now, 3D designs and machines make these shapes easier. Remember, the only thing that should be curling with your 3D prints is your toes from satisfaction!

Conclusion: Achieving Perfect 3D Prints with the Right Techniques.

Get Flawless 3D Prints With Correct Techniques!

The right techniques are key to great 3D prints. Warping and curling can be avoided with the correct approach. These issues may stem from lack of adhesion or temperature changes during printing.

One of the main considerations is proper bed adhesion. This will help stop warping. It’s also important to understand how temp affects your prints. Monitor the hot end and bed temp for best performance.

Moisture in the filament may lead to curling. Over-cooling or over-heating can cause deformations. Checking moisture before use can fix curled 3D prints.

Applying these techniques will give you perfect 3D designs. Follow all procedures for the best results.

A pal was complaining about warps despite following all the rules. We figured out that the nozzle had clogged, leading to a slow heat transfer from the printer’s hot end. The layers were under-extruded. Replacing the nozzle fixed the problem and he got flawless prints.

Frequently Asked Questions

1. What causes warping in 3D prints?

Warping occurs when the bottom layers of a 3D print cool at a different rate than the top layers. This can happen due to a variety of factors including poor bed adhesion, uneven cooling, and improper temperature settings.

2. How can I fix warping in my 3D prints?

To fix warping, you can try improving bed adhesion by cleaning the print surface or applying an adhesive such as hairspray. Ensuring a consistent print temperature and a level print bed can also help reduce warping.

3. Why do my 3D prints curl at the edges?

Curling can occur when the corners or edges of a print cool faster than the rest of the object, causing them to lift and curl upwards. This can be caused by poor bed adhesion, uneven cooling, or incorrect temperature settings.

4. How do I prevent curling in my 3D prints?

You can prevent curling by using good bed adhesion techniques such as cleaning the print surface and using an adhesive. Ensuring a consistent print temperature and cooling speed can also help reduce curling in prints.

5. Can changing the temperature of my print bed help fix warping?

Yes, changing the temperature of your print bed can help address warping issues. Increasing the temperature can improve bed adhesion and reduce the likelihood of warping, while decreasing the temperature can help prevent curling.

6. When should I consider adjusting my print temperature settings?

If you are experiencing warping or curling in your 3D prints, adjusting your print temperature settings may be necessary. You may also need to adjust temperature settings when using different materials or printing complex objects.