Contents

- Understanding Layer Shifting Issues in 3D Prints

- Checking Belt Tension to Fix Layer Shifting

- Axis Alignment to Fix Layer Shifting

- Print Speeds Impact on Layer Shifting

- Using Software to Compensate for Layer Shifting

- Maintaining Your 3D Printer to Avoid Layer Shifting

- Troubleshooting Layer Shifting in 3D Prints

- Conclusion: Fixing Layer Shifting in 3D Prints

- Frequently Asked Questions

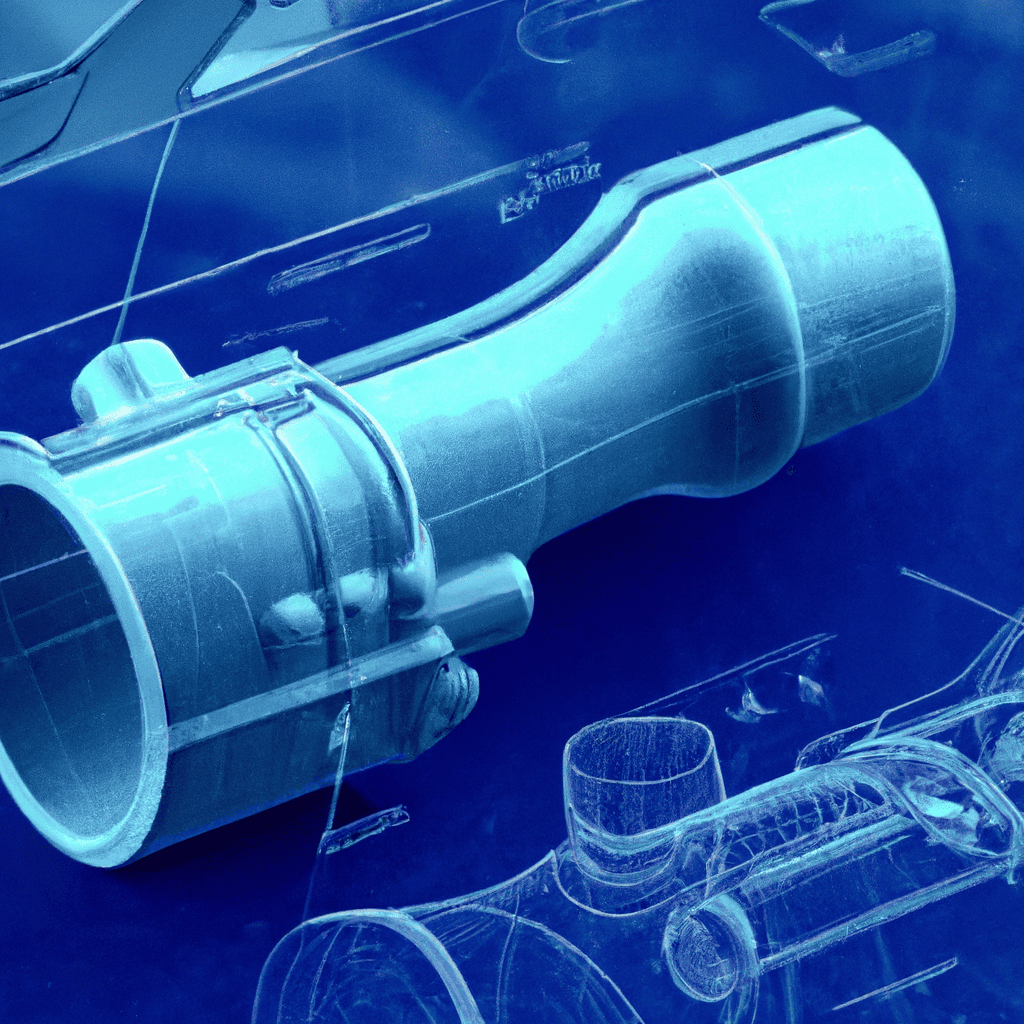

Understanding Layer Shifting Issues in 3D Prints

Layer shifting is a common issue in 3D printing. This can lead to failed prints and wasted resources. To prevent this, various factors must be taken into account. These include belt tension, axis alignment, and print speed.

These factors and their solutions are listed below:

| Factor | Explanation | Solution |

|---|---|---|

| Belt tension | Loose belts lead to inaccurate movements, causing layer shifts | Tighten the belts for accurate movements |

| Axis alignment | Misalignment can lead to layer shifting | Check and adjust all axes |

| Print speed | Too fast prints create vibrations, leading to layer shifts | Reduce the print speed |

Each factor, alone or combined, can cause layer shifting. That’s why it’s important to check everything before printing.

This way, layer shifting can be avoided and successful prints are ensured.

Did you know? According to Wohlers Associates, 3D printer sales have grown at an average rate of 25% per year for over 30 years! Tightening the belts is essential for smooth layering.

Checking Belt Tension to Fix Layer Shifting

To get a successful 3D print, belt tension must be adjusted correctly. Correctly checking Belt Tension can help fix Layer Shifting. Here are the steps to take:

- Power off and unplug the printer.

- Find the motor that powers the related axis and loosen its bracket screws.

- Tighten or loosen the belt adjustment screw until the belt has slight give when pushing at midpoint between two pulleys. Don’t overtighten or leave loose because that leads to prints with layer shifting issues.

- Gently push on each side of the motor while tightening the bracket screws again. This will center it within its brackets and maintain even tension for the belt across pulleys on either end.

- Turn the printer on and check for smooth Axis movements and no shaky or wavy X/Y/Z movements before printing again.

It’s important to keep in mind that both ends of the belt must be tight, or else uneven pressure distribution leads to layer shifting when printing. Revisit this step when necessary for the best prints.

Pro Tip: Use non-slip tweezers to avoid slipping while adjusting small screws. Get your 3D printer back in shape by aligning your axes – it’s like giving it a chiropractic adjustment.

Axis Alignment to Fix Layer Shifting

To align 3D printing layers, one must adjust the printer’s axis. Here’s how to do it:

- Turn off the printer and let it cool down.

- Detach the belt from both sides or move it along the axis to reduce tension.

- Move the axis manually in each direction; adjust or change any parts if needed.

- Connect the belt again, making sure it’s tightened correctly with the right tension. This will optimize print quality and maintain alignment.

Also, changing print speed and acceleration settings may help. Check your manufacturer’s manual for the best settings.

One user encountered layer shifting issues despite calibrating movement. After discovering a worn part caused out-of-place movement during printing, he replaced and re-aligned it. This solved his accuracy problem swiftly!

Accuracy and layer shifting can be prevented by taking it slow in 3D printing.

Print Speeds Impact on Layer Shifting

Print Speeds and their Effect on Layer Shifting.

To reduce layer movement in 3D prints, it’s important to understand how print speeds can impact it.

- Faster printing can lead to more layer shifting due to mechanical stress when accelerating and slowing down.

- Slower speeds can reduce mechanical stress, resulting in fewer errors and smoother prints.

- The best speed depends on the printer, filament, and object; so try out different speeds.

Remember to make sure your printer settings are right, as fast speeds or wrong settings can cause a lack of extrusion and other problems.

Did you know that Ultimaker did a study showing that changing print speed had a big effect on the end result?

Software can be the digital way of fixing layer shifting.

Using Software to Compensate for Layer Shifting

Software can be a great help to prevent layer shifting in 3D printing. Popular software options include:

- Cura, with layer shift compensation and g-code editing

- Simplify3D, with real-time print monitoring and custom settings

- PrusaSlicer, with automatic layer shifting compensation and optimized print profiles

It is important to remember that software cannot always completely fix all layer shifting issues. Physical adjustments are also important, such as aligning the axis and ensuring proper belt tension.

When choosing software, make sure it is high-quality and reliable. A paper by Tushar Sharma and Charu Sharma on ‘Analysis and Optimization of Layer Shifting Defects of FDM Based 3D Printing Process’ emphasizes the importance of effective calibration of machine parameters to reduce layer shifting-related problems.

Caring for your 3D printer is much like caring for a pet rock, but with less responsibility and more belt tension adjustments!

Maintaining Your 3D Printer to Avoid Layer Shifting

Maintaining 3D print accuracy is important to avoid layer shifting. Here’s how to get top-notch prints, no shifting! Follow three steps to maintain your 3D printer:

- Check belt tension. Belts that are too loose can cause axis slips, resulting in layer shifting. Make sure belts are tight and secure motor shafts.

- Align axes. Keep printer axes at precise right angles. Even a tiny offset can lead to faulty layer adhesion and distorted models.

- Optimize printing speed. Fast speed may cause vibrations, leading to uneven layers. Slow down for intricate parts or thin walls to reduce shifting.

Invest time in maintenance: it’ll save you trouble! Take care of your machine often. My friend had an unpleasant experience when his new print was accidentally bashed due to an under-tightened axis belt. He had to reprint it, but now he double-checks everything! Shift can be avoided, though. Follow these tips and your 3D prints will be perfect in no time.

Troubleshooting Layer Shifting in 3D Prints

Layer shifting is a common problem with 3D printing. Layers can become misaligned during the printing process. Here’s a 3-step guide to help fix this issue:

- Check belt tension. Looseness can cause shifting. Tighten the belts, but not too much.

- Align axes. Misalignment can lead to shifting. Check if your printer’s X-axis and Y-axis are correct and make adjustments if needed.

- Reduce print speed. High speeds can cause vibrations. Slow it down to see if it fixes the problem.

Also, clogged extruders, insufficient cooling, and wrong slicing settings can cause shifting. To avoid this, tune the acceleration and jerk controls. Limiting the rapid movements of the printer heads can reduce vibrations and improve accuracy.

Keep your printer clean, use good filaments, and create an optimal printing environment with proper ventilation and temperature control. That way, you can say goodbye to layer shifting and enjoy flawless prints!

Conclusion: Fixing Layer Shifting in 3D Prints

Text: Are layer shifts ruining your 3D prints? Follow these four steps to get perfect prints!

- Check belt tension and adjust it if needed. Loose belts can cause shifting.

- Inspect the gantry and x-axis rods for looseness or damage.

- Decrease print speed to reduce the risk of shifting due to jerks or bumps.

- Use a stiffer filament to make the model more rigid.

Remember to also check if stepper drivers are overheating. This can cause shifts or skips.

Did you know that old 3D printers lacked proper calibration, causing major layer shifting? But now, modern 3D printers provide detailed customization options to fix mechanical issues while printing.

Frequently Asked Questions

Q: What causes layer shifting issues in 3D prints?

A: Layer shifting can be caused by a number of factors including a loose belt tension, misaligned axes, incorrect print speed settings, or software/hardware malfunctions.

Q: How can I fix belt tension issues to prevent layer shifting?

A: To fix belt tension issues, you will need to adjust the tension of the belt securing the stepper motor to the axis. Simply loosen the screws holding the motor in place, adjust the belt tension, and tighten the screws back up accordingly.

Q: How do I align the axes to correct layer shifting issues?

A: To align the axes, you will need to check the alignment of the rods or carriages running along each axis. Use a spirit level to ensure that the rods are running parallel to each other and make any necessary adjustments to correct the alignment.

Q: Can print speed affect layer shifting in 3D prints?

A: Yes, print speed can affect layer shifting. If the print speed is too fast, it can cause the extruder to push too much filament, resulting in layer shifting. Adjusting the print speed can help prevent this issue.

Q: How can I prevent layer shifting in future prints?

A: Preemptively preventing layer shifting can best be done by regularly checking belt tension, axis alignment, and print speed. Running test prints can also help identify any issues before they become problematic.