Contents

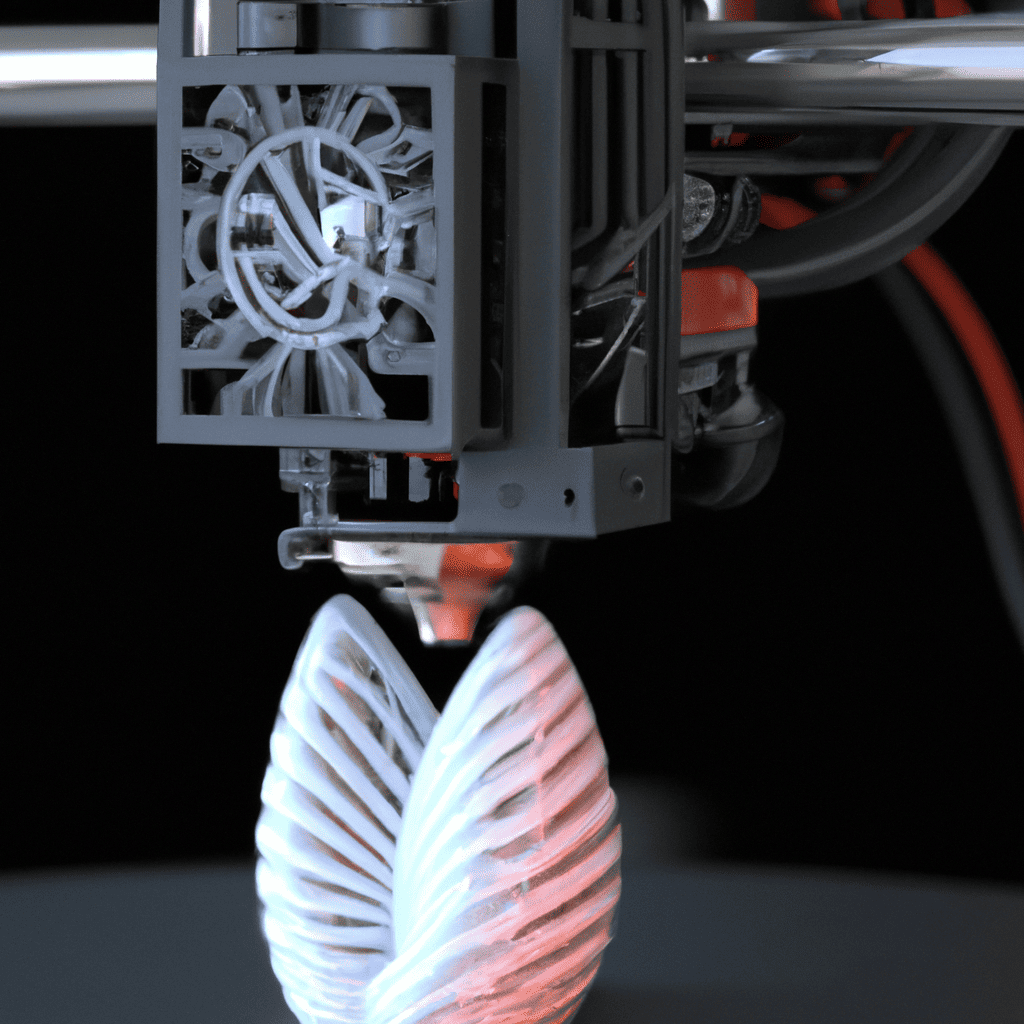

Understanding the Problem of a 3D Printer Starting Too High

When a 3D printer starts too high, it can cause failed prints due to bad adhesion between filament and bed. This can be irritating, particularly when it happens again and again. Fortunately, there are solutions!

- Bed Leveling. Check the level of your bed with a guide, like a piece of paper or feeler gauge.

- Adjust Z-Offset. Change the Z-offset before printing. Use software, like Cura or Repetier-host, if your printer doesn’t have this feature.

- Increase First Layer Height. If Z-offset doesn’t work, increase the first layer height for better adhesion and to avoid warping.

Every printer is different and may need different approaches. But these steps are a good place to start for beginners.

Test print after making any changes to check if they worked. If nothing helps, upgrade your printer hardware and system for best performance.

Don’t worry – with patience and some effort, you can get back to printing perfect models. No need to throw your printer out the window!

Troubleshooting the Issue

To troubleshoot the issue of your 3D printer starting too high, here’s what you can do: check the bed leveling and adjust the Z-offset. These two sub-sections can help identify and solve the problem, ensuring that your 3D printer starts at the right height and produces accurate prints.

Checking Bed Leveling

When it comes to ensuring optimal printer performance, keeping the printer bed leveled is key. Here’s how:

- Grab a piece of paper and place it in the middle of the bed.

- Adjust the bed until there’s enough friction to keep the paper from sliding out from under the nozzle.

- Do this for the four corners of the bed.

- Monitor multiple layers if prints remain unresolved after adjusting the bed leveling screws.

- Make sure there are no physical obstructions or remnants on either your calibration tool or plate/template. Remove any anomalies before commencing calibration.

Remember to check the manufacturer’s instructions – they can differ. Proper calibration will lead to improved printing quality and help avoid failed prints or jamming issues.

Now, a true story: I worked with an engineer who had been battling an issue with his home printer for months. Tried every possible solution and modifications with no luck. Then he realized that the printer was never properly calibrated to begin with. After recalibrating, the results were impressive.

No need for a construction level – just use your eyes and steady hands (or a glass of wine).

How to Properly Level the Bed

If you’re having troubles with your printer, it could be due to it not being level. It’s important for good prints and the life of your printer. To make sure it’s level, try these steps:

- Heat up the printer to the temperature for your filament.

- Manually adjust each corner so they’re the same distance from the nozzle. Use paper to check.

- Choose “Auto Home” on your printer.

- Use a dial indicator or other tool to double-check the level. Make changes if needed.

- Repeat steps 2-4 until all corners are level.

- Save your settings so you don’t have to level again.

It’s important to remember that a bad level can cause adhesion problems or damage your 3D printer. Plus, a sticky polymer film like PEI sheets can help with adhesion and taking off prints. Auto-leveling is also useful for extra reliability. So make sure you get a good night’s sleep with an even bed.

How to Adjust the Bed Leveling Screws

Ensure smooth and accurate prints by adjusting your 3D printer’s bed leveling screws. Follow these steps for better results:

- Turn on your printer and heat the build platform and extruder nozzle.

- Place a sheet of paper on the build platform.

- Home all axes for calibration.

- Adjust the bed leveling screws until you feel a slight resistance when sliding the paper between nozzle and build surface.

- Repeat for all corners to achieve an even gap.

- Rehome all axes and recheck leveling. Make any additional adjustments as needed.

Remember to save the settings for consistent future prints. Re-check and adjust the bed level regularly, especially if you move or change your printer’s location, or if you notice warping issues with printed parts. Get perfect prints by following these easy steps today!

Adjusting the Z-Offset

To adjust the Z-Offset:

- Home your printer.

- Disable any active leveling.

- Create a gap using paper between the nozzle and bed.

- Select “Z offset” from the menu and lower the value till you feel resistance when taking out the paper.

- Check for any resistance by slipping another piece of paper between the bed and nozzle.

- Save the new settings.

Remember, an improper Z-Offset can lead to uneven layers in your prints.

Pro Tip: Adjusting once is not enough. Temperature changes may affect calibration. Make sure to repeat this regularly for better accuracy. Z-Offset: the one thing preventing your printer from a collision with the bed.

What is Z-Offset?

The Z-Offset is the gap between the printer nozzle and the print bed. It’s very important to get this setting right for good adhesion and quality prints.

A table with columns ‘Issue’, ‘Cause’ and ‘Solution’ can help with Z-Offset issues. For example, ‘Print not sticking to bed’ could be due to the Z-Offset being too high. The solution would be to reduce the Z-Offset.

Different printer models may need different settings. This means you may have to test various offsets until you find the right one.

You should calibrate the Z-Offset before printing every model to avoid wasted resources and reprinting. Fixing Z-Offset problems is key to prevent your 3D prints from looking like modern art. It might be tricky, but it’s a minor tweak that will make a big difference!

How to Adjust the Z-Offset

To achieve superb 3D prints, adjusting the Z-Offset is a must! Here’s what you must do:

- Home your printer or move the print head to its starting position.

- Then, place a sheet of paper or feeler gauge between the bed and nozzle.

- Adjust the Z-axis until the paper or gauge slides back and forth with slight resistance.

Keep in mind that the Z-Offset is only one of many aspects of 3D printing. Paying attention to every step is the key to successful prints. Otherwise, bad prints and uneven layers will be the outcome.

Take control of your 3D printing process now and make sure to adjust your printer’s Z-Offset! Enjoy perfect prints for years to come! And most importantly, never leave your computer unplugged and live like a hermit to avoid any issues!

Tips for Preventing the Issue

To prevent the issue of a 3D printer starting too high, follow these tips with four sub-sections for the solution. Regularly check bed leveling, calibrate the Z-offset, use a calibration cube, and use a different starting G-Code.

Regularly Check Bed Leveling

For optimized printing, check your bed level! A 6-step guide:

- Home printer and disable stepper A.

- Manually adjust each corner with a sheet of paper until there’s no slide.

- Repeat twice and fine tune.

- Print a large square to check levelness.

- Look for gaps or bubbles.

- Make fine-tuning adjustments until perfect.

Remember to check your bed level often, and don’t move your printer once it’s calibrated. Calibrating the Z-Offset? Like finding the G-spot – practice makes perfect!

Calibrate the Z-Offset

Making your prints ace? It’s all about adjusting the z-axis position, also known as fine-tuning the height between the print bed and nozzle. Here are five steps for better results:

- Get the equipment in place.

- Use a calibration cube or 3D print object as reference.

- Change the nozzle height using software or printer control panel.

- Print the cube and adjust the z-axis until quality prints.

- Keep repeating until you get the right settings.

You need to calibrate z-axis at times, else it can cause issues like poor adhesion, layering and extrusion.

Pro Tip: Remember to check the Z-Offset setting after any firmware update.

And of course, use a calibration cube for perfect 3D prints!

Use a Calibration Cube

Maximize Printing Quality with Calibration Cube!

To get precise prints, using a calibration cube is essential. Here’s how:

- Print the Cube

- Download a cube from a reliable site or design it yourself with Tinkercad or similar software.

- Print the cube with the same settings as your standard prints.

- Analyze the Cube

- Check the first few layers to ensure they stick to the printer bed.

- Examine all sides for issues like stringing, layer separation, and uneven layer lines.

- Assess Results

- Study the symmetry of each face to spot any errors.

- If there are any mistakes, adjust your printer settings and reprint until you’re satisfied.

- Adjust Settings

- Fine-tune your machine before printing more complex items (e.g. blueprints and prototypes).

Using this tool reveals small printing inaccuracies and helps dramatically improve performance.

Optimize Your Printing with Calibration Cube

Achieve top-notch printing quality every time by making calibration a regular part of your process – you’ll be getting great results in no time!

Transform your G-Code skills and avoid printing fails.

Use a Different Starting G-Code

To avoid printing errors, modify the starting G-code. Change the workflow or add new code that addresses printer issues. Here’s a 3-step guide:

- Identify problems with current code. Poor bed adhesion, unsupported travel moves, and over extrusion could be some.

- Customize Starting G-code. Make corrections to address identified issues.

- Test and Validate Changes. Verify if the updated code fixes the issue and produces successful prints.

Using a different starting G-code increases safety. It also may improve productivity for complex components. Adopting personalized Starting G-code reduces time-wasted calibrating each print.

Many users have wasted filament on test prints before testing new start-up codes. Consider configurations like cooling rates and extrusion speed to minimize micro-adjustments.

Fixing a 3D printer starting too high is tricky but doable.

Conclusion: Successfully Fixing a 3D Printer Starting Too High

When you’re dealing with a 3D printer that’s starting too high, you need the right troubleshooting techniques. Here’s a guide to help you out:

- Check the settings and recalibrate the bed level.

- Adjust the Z-offset in the firmware.

- Inspect the extruder and make sure it’s tight.

- Clean the build plate and keep it dust-free.

- If nothing else works, try updating or reinstalling the firmware.

Remember, every 3D printer model is different, so you may need to do some extra research. I know what it’s like to face this issue. After wasting hours trying to fix it, I found help from community forums and guides. It’s a relief knowing there are so many resources out there.

Frequently Asked Questions

Q: What does it mean when my 3D printer starts too high during a print?

A: When your 3D printer starts too high, it means that the print head is too far away from the build surface, which can cause poor adhesion and failed prints.

Q: How do I troubleshoot a 3D printer that starts too high?

A: First, check that your bed leveling is correct, as an uneven build surface can cause the print head to start too high. Next, adjust the Z-offset to lower the print head closer to the build surface. Finally, ensure that your printer is calibrated properly.

Q: What is bed leveling, and how does it affect the print start height?

A: Bed leveling is the process of adjusting the build surface to ensure that it is level and even. If the bed is not level, the print head can start too high or too low, causing issues with adhesion and print quality.

Q: How do I adjust the Z-offset on my 3D printer?

A: To adjust the Z-offset, you will need to access your printer’s firmware settings. This can usually be done through your printer’s control panel or via a computer connection. Look for the Z-offset setting and adjust it accordingly, lowering the print head closer to the build surface.

Q: What other troubleshooting steps can I take to fix a 3D printer that starts too high?

A: Try cleaning the build surface to ensure that it is free of debris or residue that could affect adhesion. Additionally, double-check your slicer settings to ensure that they are configured correctly for your printer.

Q: How important is it to fix a 3D printer that starts too high?

A: It is essential to fix a 3D printer that starts too high, as this issue can cause failed prints, wasted materials, and frustration. Addressing this issue will ensure that your printer is functioning correctly and producing high-quality prints.