Contents

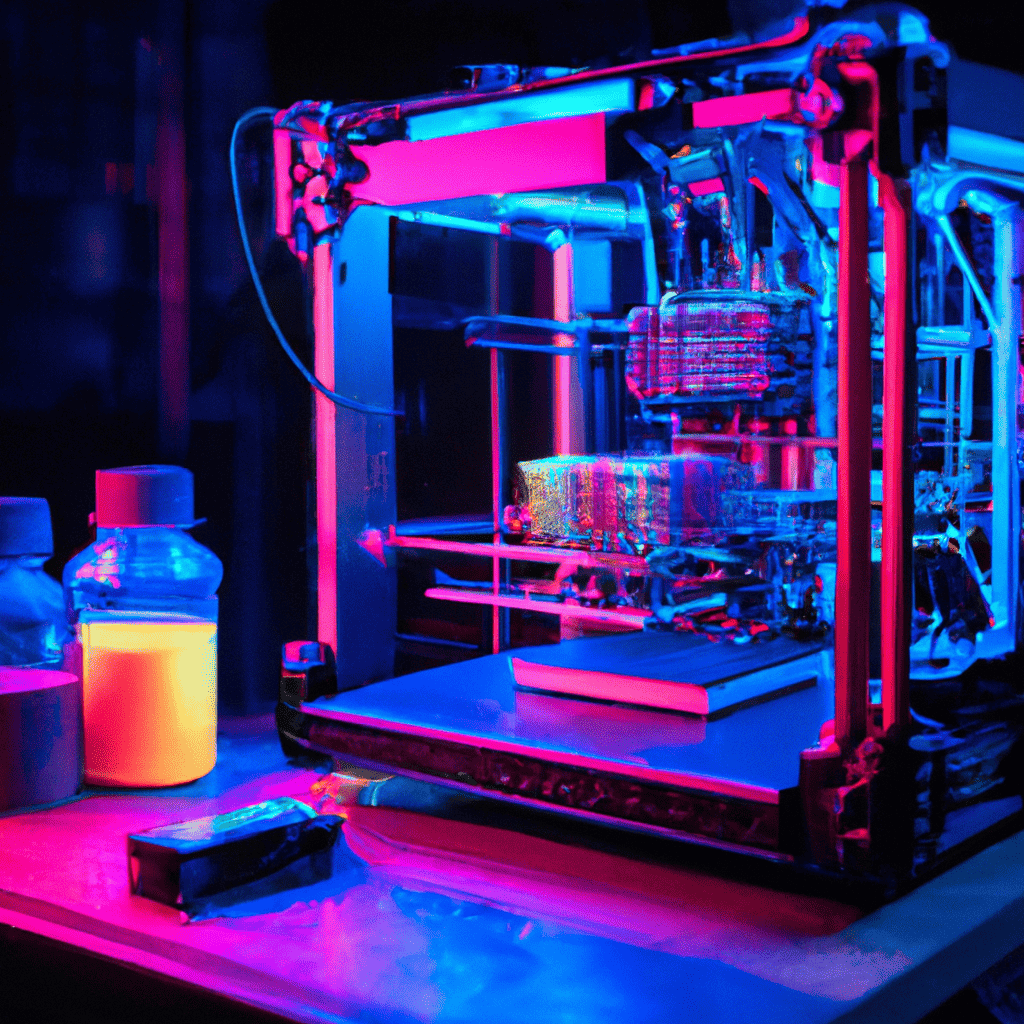

Overview of 3D Printer Resin

3D printing uses resin-based technology to transform digital ideas into physical objects. Resins are polymers that solidify when exposed to UV light. Different types of resin and their quality can determine the printing results. Price, thickness, color, and durability are all things to consider.

| Resin Type | Print Volume | Lifespan per Liter |

|---|---|---|

| Standard Resin | 0.5-1 liter | 20-30 hours (normal use) |

| Durable Resin | 0.5-1 liter | 10-20 hours (normal use) |

| Flexible Resin | 0.5-1 liter | 15-25 hours (normal use) |

The amount of resin used for a model depends on its size, complexity, and density. Generally, one liter makes 10-50 small or medium prints (or 2-10 big ones) before it’s time to replace it.

Pro Tip: To get the most out of your resin, store it in a cool and dark place. Also, keep it covered with its original lid to avoid any dust or debris getting inside. The lifespan of resin is determined by multiple elements, but don’t worry, it’s not rocket science…unless you’re 3D printing rockets!

Factors Affecting Resin Usage

To optimize your resin usage when 3D printing, understanding the factors that affect the amount of resin used is crucial. This section on “Factors Affecting Resin Usage” with “Print Volume, Type of 3D Printer, Print Settings and Resolution” as sub-sections will provide insight into the key factors you should consider. By paying attention to these details, you can extend the lifespan of your resin and save money in the long run.

Print Volume

Print Yield is a major factor that impacts resin use in printing. It is the total amount of material printed with a particular resin. Knowing the Print Yield can help control the resin use, as more print volume per unit of material can lead to less resin being consumed.

For example:

| Print Volume | Material Used | Resin Consumed |

|---|---|---|

| 100 mL | 130 g | 20 g |

| 200 mL | 250 g | 40 g |

| 300 mL | 350 g | 60 g |

However, more print volume does not always mean lower resin consumption. Different print models, resolutions, and designs can all affect the print yield, and require different amounts of resin. Tuning the print settings for a particular application is key.

Trying out new infill patterns, changing the number and thickness of the shells, and using good quality resins from dependable suppliers, are all useful tactics for achieving maximum print yield while reducing resin usage. High-quality resins are often more effective, allowing for more efficient utilization.

So, in summary, considering print yield and optimizing settings are essential for controlling resin usage during printing. Experimenting with different parameters and using good materials will help you reach your desired results in a more efficient way, with less waste. When it comes to 3D printing, selecting the right printer is like selecting the right partner – it’s all about compatibility and avoiding a mess.

Type of 3D Printer

Various 3D Printer Models play a major role in the quantity of resin needed for each printing process. The printer’s capacity, print bed size and resolution have an effect on resin usage.

Check out this table to see the impact of different 3D Printers on resin usage:

| Printer Model | Print Bed Size (inches) | Resolution (microns) | Resin Usage per Hour (millilitres) |

|---|---|---|---|

| MakerBot Replicator+ & Z18 | 11 x 7.6 | 100-400 | 5-10 |

| Formlabs Form 2 & 3B | 5.7 x 5.7 x 6.9 | 25-100 | 1-4 |

Certain printers are designed to work better with particular types or brands of resins, which can further affect consumption levels.

Did you know? Dr Hideo Kodama first proposed 3D printing in 1981. He suggested using photopolymer that solidifies when exposed to light to make three-dimensional plastic models.

In conclusion, it is important to be aware of the differences between printer models to set the correct amount and type of resin for successful printing. Don’t worry, with low print resolution your resin project will look stylish with intentional cracks!

Print Settings and Resolution

Print Quality and Clarity have a huge impact on resin usage in 3D printing. Here’s how:

| Print Settings and ResolutionPrint Quality and ClarityResin Usage | ||

|---|---|---|

| High Resolution | High Quality | More Usage |

| Medium Resolution | Medium Quality | Moderate Usage |

| Low Resolution | Low Quality | Low Usage |

Print size, layer height, and infill percentage are key factors affecting resin consumption. High resolution can boost print quality – but also increase resin usage.

So, to save resin, try lower resolutions that still meet your desired quality. You can also reduce infill percentage without much effect on strength or accuracy. Resin may be tough – but it can’t beat my ex’s grudge!

How Long Does a Liter of Resin Last?

To calculate how long a liter of 3D printer resin lasts for you, turn to this section about “How Long Does a Liter of Resin Last?”, with a focus on “Calculation of Resin Usage” and “Estimated Lifespan of Resin” as solution points. These sub-sections will provide brief insights into determining resin usage and how long can you use it before it expires.

Calculation of Resin Usage

Calculating Resin Usage is key for proper production planning and budgeting. It’s essential to know how much resin is needed for a project or task.

This table provides an overview of resin usage for different applications. It has columns for Material Type, Volume, Density, and Weight. Input the values for these parameters and calculate the right amount of resin.

| Material Type | Volume | Density | Weight |

|---|---|---|---|

| Fiberglass Matting | 100 ft² | 1.5 oz/ft² | 7.5 lbs |

| Carbon Fiber Felt | 50 yd² | .014 inch thickness | 10 lbs |

| Epoxy Resin | 2 gallons | 1.1 g/cm³ | 19 lbs |

| Polyester Resin with Catalyst | 1 gallon + .25% catalyst by wt. | ~9 lbs/gal. | ~10 lbs |

Different projects need different amounts and types of resin depending on the material and application.

A Pro Tip: Always calculate extra resin usage, because unexpected situations could lead to more consumption. Resin may last, but chances are, we’ll lose it before it reaches its estimated lifespan.

Estimated Lifespan of Resin

How Long Does Resin Last?

It depends. Usually, a liter of resin lasts for 6 months to 1 year. We made a table to show its lifespan:

| Storage Temp | Lifespan |

|---|---|

| 15-20°C | 6 months – 1 year |

| Above 30°C | < 6 months |

| Below 10°C | > 1 year |

Temperature plays an important role. Also, other factors such as careful handling, light and moisture exposure, and proper maintenance affect its durability.

For best use and longer life, store it in a cool, dry place away from sunlight. Make sure to seal containers tightly after each use to avoid air moisture.

By following these steps, you can extend your resin’s lifespan and get amazing results in your projects. Maximizing its life is a wise decision, like keeping your ex’s phone number on speed dial.

Best Practices to Extend Resin Lifespan

To extend the lifespan of your 3D printer resin and optimize your 3D printing sessions, implement these best practices. With proper storage of resin, cleaning and maintaining the 3D printer, and choosing the right type of resin, you can save on the cost of the material and ensure consistent, high-quality prints.

Proper Storage of Resin

Optimizing Resin Storage

In order to ensure the best possible performance and longevity of resin, it’s important to carefully consider storage procedures. Maintaining a suitable temperature and stable environment, free from excessive heat, moisture, and sunlight exposure, is crucial. Proper storage techniques help prevent lower shelf life, reduced performance, and degraded material quality.

To optimize resin storage, keep resin in a dark spot away from direct sunlight and UV rays. Store in an air-conditioned area with a temperature ranging from 25-30°C. It is important to note that refrigeration is not the best choice for storing resin. Low temperatures can increase viscosity, making the material unusable.

For large amounts of resin, rotate stock by using older inventory first before introducing fresh stock. Additionally, label each container with the production date for easy record keeping.

When resin is stored properly, it can last for years without degrading in quality or performance. Utilizing correct storage procedures ensures that long-term viability is maintained while also ensuring optimal results. Keep your 3D printer clean and it will reward you with a longer resin lifespan.

Cleaning and Maintaining the 3D Printer

For optimal performance and long life of your resin 3D printer, maintenance and cleaning are a must! Here are five simple steps to get you started:

- First, unplug the printer.

- Clean the resin vat, remove any residue.

- Be sure to clean the build platform, no residue left.

- Use a scraper or spatula to remove any cured resin.

- Finally, wipe down the exterior with a dry cloth to get rid of dust or debris.

If neglected, your printer’s performance and prints could suffer. So, clean it after every use for superior results.

Don’t forget about calibration – you need to do it when printing bed or parts like nozzles are changed. Failing to do so will have a bad impact on print quality.

Pro Tip: Cleaning the resin tank and build platform with isopropyl alcohol regularly prolongs their lifespan and improves prints. Choose the right resin for best results – compatibility and longevity are key!

Choosing the Right Resin

To guarantee the long-life of resin, it’s vital to pick the right type. Here’s a breakdown of what to use for certain traits:

- Low Viscosity – Epoxy Resin;

- UV Resistance – Polyester Resin;

- High Heat Tolerance – Phenolic Resin.

Also, factor in the project’s needs – flexibility & rigidity. Don’t settle for inferior quality – go for the better option! A customer picked a cheaper resin once and it didn’t work out. It cracked and changed color after just a few months.

Make sure to get the best quality to avoid this kind of disaster. Follow these tips and your creations will last longer than cockroaches after a nuclear holocaust!

Conclusion and Final Thoughts

The Lifespan of 3D Printing Resin

When it comes to the life of 3D printer resin, there’s lots to consider. Volume of prints, environmental conditions and storage are all important.

A liter of resin can last a long time – it depends on several factors. To get the most out of your resin, use good environment and storage practices.

Here’s a tip: Store your resin in a dark, opaque container. Keep it away from direct sunlight for the best shelf life.

Frequently Asked Questions

1. How much resin can a liter of 3D printer resin print?

The amount of resin a liter can print depends on several factors, including the size and complexity of the printing object and the printer settings. However, as an average, a liter of 3D printer resin can print approximately 800-1000 milliliters of resin.

2. How long does a liter of 3D printer resin last?

The lifespan of a liter of 3D printer resin depends on various factors, such as the frequency of printing, the size of the printing object, and the settings of the printer. However, in general, a liter of 3D printer resin can last for a few months to a year.

3. How can I extend the lifespan of my 3D printer resin?

You can extend the lifespan of your 3D printer resin by storing it in a dry and cool place, away from direct sunlight. It would be best if you also kept the resin container sealed tightly to prevent it from getting contaminated by moisture and dust.

4. Does the print volume affect the lifespan of my 3D printer resin?

Yes, the print volume can affect the lifespan of your 3D printer resin. Prints that require more resin to complete will deplete your resin supply faster than small prints. Therefore, it is essential to have an accurate estimate of the resin volume required before starting the print job.

5. Can I reuse my 3D printer resin?

Yes, you can reuse your 3D printer resin to a certain extent. You can recycle the leftover resin by straining it through a fine mesh filter to remove any solid particles that may have accumulated. However, note that recycled resin may not perform as well as fresh resin and may affect the print quality.

6. Is it safe to dispose of 3D printer resin?

No, it is not safe to dispose of 3D printer resin into regular trash. Resin contains chemicals that can harm the environment, so it is essential to dispose of it properly. You can contact your local authorities to inquire about proper disposal methods or take it to designated waste-management facilities.