Contents

- Introduction

- What is a 3D Printing Glass Bed?

- Borosilicate Glass Bed for 3D Printing

- Tempered Glass Bed for 3D Printing

- Thermal Stability of Glass Beds for 3D Printing

- Adhesion on Glass Beds for 3D Printing

- Comparison of Borosilicate and Tempered Glass Beds for 3D printing

- Conclusion

- Frequently Asked Questions

Introduction

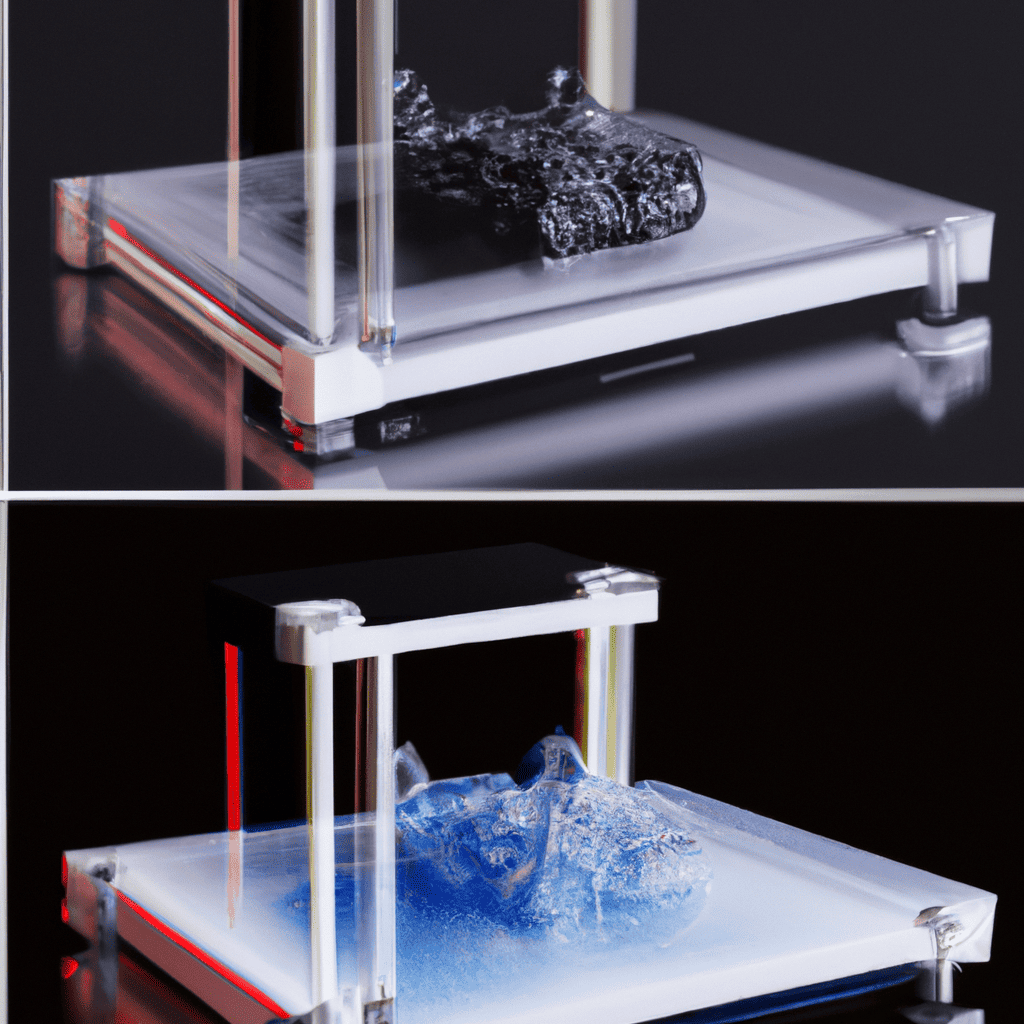

For 3D printing, the glass bed you choose can influence the quality of your prints. Borosilicate and tempered glass are popular materials. Borosilicate glass is great for high-temperature printing because of its thermal stability. Tempered glass is shatter-resistant and provides more safety.

Adhesion is good with either choice, when you use an adhesive like hairspray or glue. Some people find that borosilicate glass offers a smoother surface finish and better print quality because of its thermal stability.

Which one is best for you? Consider the materials you’ll be printing with, the highest temperature your printer can reach, and safety issues. Don’t miss out on good prints – explore the pros and cons between borosilicate and tempered glass beds now! Ready to start 3D printing? You need the right glass bed.

What is a 3D Printing Glass Bed?

To achieve optimal results with your 3D printing, switch to a glass bed. In this section on “What is a 3D Printing Glass Bed?”, we will explain the importance of a glass bed in 3D printing. You’ll learn about the advantages of using a glass bed for thermal stability and adhesion.

The Importance of a Glass Bed in 3D Printing

Printing on glass beds is vital for quality output. Why? Glass provides a smooth surface for accurately printing high-quality products. Without a glass bed, your prints will be rough and low-quality.

The importance of a glass bed in 3D printing? Let’s review:

| Importance | Description |

| Flat Surface | A flat printing surface makes the printing process more convenient. |

| No Wrapping | Gives stability and holds the print firmly as it forms. |

| Better Adhesion | Improves bed-to-print bonding, resulting in better adhesion of prints. |

Plus, glass beds are easy to clean and extend the lifespan of your printer bed. Don’t miss out on top-notch output quality! Make sure to choose the ideal 3D printing glass bed for your needs and preference today!

Borosilicate Glass Bed for 3D Printing

To achieve the best results in 3D printing with thermal stability and exceptional adhesion, you need a reliable and durable printing bed. In this section of the article on Borosilicate Glass Bed for 3D Printing, we will explore the advantages and limitations of Borosilicate glass beds. From superior thermal stability to a significant reduction in warping, Borosilicate glass beds have a lot to offer for 3D printing. However, like any other material, there are a few limitations that you need to consider.

Advantages of Borosilicate Glass Bed

Pyrex® is a popular type of borosilicate glass that offers multiple advantages for 3D printing enthusiasts. It provides a stable, flat surface for seamless printing. Plus, it’s resistant to thermal shock, so it will last for a long time. Cleaning is easy, too! The non-porous surface allows you to quickly remove excess filament materials after printing.

ScienceDirect research has also found that Borosilicate Glass Bed increases adhesion and reduces print failures. So, if you’re looking for an ideal 3D printing surface, choose Borosilicate Glass Bed! You won’t be sorry.

Limitations of Borosilicate Glass Bed

Borosilicate Glass Bed is a popular 3D printing choice due to its thermal resistance & adhesive qualities. But, it can be fragile & prone to cracking or breaking. It also requires regular cleaning & may warp with materials like ABS.

Alternatively, BuildTak or PEI sheets may provide better strength. Yet, Borosilicate Glass Bed is still reliable for heat distribution & adhesion.

Plus, it’s often used in labs because of its resistance to high temperatures & thermal shock. Upgrade your 3D printing with tempered glass – like using a fancy mechanical pencil!

Tempered Glass Bed for 3D Printing

To achieve optimal 3D printing results with your machine, you need to consider the type of glass bed you choose. In order to explore the option of using a tempered glass bed, which is less common than borosilicate, this section will examine the advantages and limitations of this type of glass bed.

Advantages of Tempered Glass Bed

Treated with respect, a tempered glass bed can last indefinitely due to its resilience against wear and tear. It ensures good adhesion, offers an even surface, and is durable and reusable. Moreover, it’s versatile in usage across different types of filaments, such as PLA, ABS Nylon, and others. Prusa Research recently made a thermochromic textured paste which changes color when heated properly. These benefits enhance the process of 3D printing.

But if your 3D prints are perfect every time, the tempered glass bed’s limitations are simple: it can’t make you breakfast!

Limitations of Tempered Glass Bed

Using a ‘Tempered Glass Bed’ for 3D printing has its benefits, but there are also certain limitations. It’s essential to be aware of these limitations to prevent any printing issues. Here’s a list of the main ones:

| Limitation | Description |

|---|---|

| Narrow range of materials | Works best with materials needing high bed temp and stable adhesion. e.g. Nylon and PETG. |

| Fragility | Can break easily with sharp impacts. Can be damaged when removing prints and cleaning. |

| Cleaning challenges | Abrasive cleaners can scratch the surface. Also, glass tends to attract grease and fingerprints. |

The thermal stability of tempered glass makes it a great choice. To extend its life, it’s best to handle it carefully while removing prints, avoid contact with foreign objects or liquids, use soft non-abrasive cleaning tools and keep away from extreme temperatures.

Thermal Stability of Glass Beds for 3D Printing

To achieve optimal 3D prints, thermal stability of glass beds is crucial. If you’re wondering which type of glass bed to use, borosilicate or tempered, this section with its sub-sections: Effect of Temperature on Borosilicate Glass Bed and Effect of Temperature on Tempered Glass Bed, will help you gain insights into the thermal behavior of both types of glass beds and choose the one that is most suitable for your 3D printing needs.

Effect of Temperature on Borosilicate Glass Bed

When it comes to 3D printing, the thermal stability of glass beds can be affected by temperature. A table has been made to show the behaviour of borosilicate glass at different temperatures. The table displays an upwards trend for the coefficient of thermal expansion as the temperature rises. Plus, the yield strength and Young’s modulus of elasticity tend to reduce with increased temperatures.

What’s special about borosilicate glass is its thermoelasticity. This quality allows small and reversible deformations when exposed to high-temperature variations. Therefore, it is a popular choice for 3D printing beds.

Research from ‘Polymers‘ journal supports the use of borosilicate glass beds, as it helps to enhance the surface quality and accuracy in 3D printing processes. But even tempered glass can’t handle the heat when it comes to 3D printing. Prepare for some heated experiments!

Effect of Temperature on Tempered Glass Bed

The stability of tempered glass beds used in 3D printing is influenced by temperature changes. It’s important to understand how it affects them, so damage and defects won’t occur.

The thickness and chemical composition also play a part in thermal stability. Factors like heat distribution, cooling rates, and material properties should be taken into account.

Monitoring and controlling temperature during each stage of printing is essential for stable, consistent results. Plus, proper handling and maintenance will ensure long-term use.

In bad cases, overheating or sudden cooling can cause dangerous thermal shocks that can harm people and printers. Thus, all aspects should be checked before attempting to work with high-temp glass beds. Printing on glass is tricky; adhesion is key to prevent a shattered creation.

Adhesion on Glass Beds for 3D Printing

To achieve optimal adhesion in 3D printing, it’s crucial to have a glass bed that provides excellent thermal stability and surface flatness. In order to improve adhesion on glass beds, there are various methods that you can utilize. These will be discussed in the upcoming sub-sections, including techniques that work well for borosilicate and tempered glass beds.

Methods for Improved Adhesion on Glass Beds

Struggling with adhesion on glass beds for 3D printing? Fear not! Here’s a 5-step guide to help.

- Clean bed with isopropyl alcohol and cloth.

- Apply thin layer of glue stick or hairspray to bed.

- Adjust bed level and nozzle height.

- Print at appropriate temp and speed.

- Let print cool before removing.

Plus, specialized products like BuildTak and PEI sheets can improve adhesion for certain materials. Don’t miss out – try these techniques and see improved results soon!

Comparison of Borosilicate and Tempered Glass Beds for 3D printing

To Comparison of Borosilicate and Tempered Glass Beds for 3D printing with Key Differences between Borosilicate and Tempered Glass Beds, Which Glass Bed to Choose for 3D Printing? as solution. The choice between borosilicate and tempered glass beds is crucial for the success of your 3D printing. Understanding the key differences between these two types of glass beds can help you decide which one to choose for your specific printing needs.

Key Differences between Borosilicate and Tempered Glass Beds

To compare Borosilicate and Tempered Glass Beds for 3D printing, we must look at their unique compositions. Viewing a Table with relevant Columns can show the distinct features of both types. Borosilicate is known for resistance to thermal shock, flatness tolerance and chemical durability. On the other hand, tempered glass has hardness, fracture toughness and impact strength.

The ways these glasses work also differ. Borosilicate has low CTE (Coefficient of Thermal Expansion), which fights warping during printing.

It is important to consider your filament needs when selecting a glass bed because it affects print quality and adherence to the bed surface. Some filaments stick better to Borosilicate than others due to its design. Moreover, proper care and cleaning will increase the lifespan and use of your chosen glass bed.

Choosing between these two types for 3D printing is like choosing between a supermodel or a millionaire – you’ll get a great print either way.

Which Glass Bed to Choose for 3D Printing?

Choosing a glass bed for 3D printing is key for achieving desired print quality. There are two types to consider – borosilicate glass beds and tempered glass beds.

Borosilicate glass beds heat up quickly and are durable and scratch-resistant, but may not be compatible with all printers. Tempered glass beds are more affordable and compatible with most printers, but take longer to heat up and are fragile.

Cost and printer specifications should be taken into account when selecting a glass bed. Decide wisely and don’t miss out on great results! With the right choice, your glass bed will surely handle those hot and steamy 3D printing sessions.

Conclusion

Selecting a glass bed for 3D printing? Borosilicate and tempered glass are two main choices. Each has their own benefits. The variation in thermal stability and adhesion makes a great difference in print quality.

Borosilicate glass has better thermal stability. It can handle temperature changes more than tempered glass. But not as sticky for adhesion. Tempered glass gives excellent adhesion due to its rough surface. However, its thermal stability is lower.

The choice between borosilicate and tempered glass depends on what you need. The materials you use for printing too. Accessories, such as adhesive sprays or tapes, can improve print quality regardless of the choice.

Optimize 3D printing experience with borosilicate or tempered glass bed? Clean the surfaces and check for cracks or scratches regularly. This is called maintenance.

Frequently Asked Questions

Q: What is the difference between borosilicate and tempered glass bed for 3D printing?

A: Borosilicate glass is made from a mixture of boron, silicon, and oxygen, which results in a glass product that has higher thermal stability and is able to withstand a wider range of temperatures. Tempered glass, on the other hand, is a heat-treated glass that is more resistant to breakage and is often used in applications that require higher safety standards.

Q: Which glass bed is better for 3D printing?

A: It depends on your specific needs. Borosilicate glass is generally preferred for 3D printing because of its thermal stability, which leads to better adhesion between the printed object and the bed. However, tempered glass is more durable and less prone to breakage, which can be an advantage in some applications.

Q: Do I need to use a glass bed for 3D printing?

A: While it is not strictly necessary to use a glass bed for 3D printing, many users prefer it because it offers a smoother surface, better adhesion, and easier removal of the printed object. A glass bed also provides better heat distribution, which can be important for achieving accurate and consistent results.

Q: What are the advantages of using borosilicate glass for 3D printing?

A: Borosilicate glass offers several advantages for 3D printing, including higher thermal stability, better adhesion, and the ability to withstand higher temperatures. This helps to prevent warping and curling of the printed object, resulting in better quality prints. Borosilicate glass is also highly resistant to chemical corrosion and abrasion, making it a durable option for long-term use.

Q: What are the advantages of using tempered glass for 3D printing?

A: Tempered glass is a strong and durable option for 3D printing that is less likely to break or shatter than other types of glass. It is also more resistant to scratches, which can help to prolong the life of the glass bed. Tempered glass is also able to withstand extreme temperatures, making it a good choice for high-temperature applications.

Q: How do I clean and maintain my glass bed for 3D printing?

A: To clean a glass bed, simply wipe it down with a damp cloth to remove any debris or residue. It is important to avoid using harsh chemicals or abrasive materials, as these can scratch or damage the glass. If you notice any buildup of residue or adhesives, you can use rubbing alcohol or acetone to clean the surface. Be sure to handle the glass bed carefully to avoid accidental breakage or damage.